How TESCAN TENSOR Enhances STEM Usability for Research

Effortless STEM Results with TESCAN’s User-Friendly Microscopes

When advanced Scientific Applications, Expert Systems Automation,

and User Experience Design come together

The purpose of a scientific instrument is to produce data which leads to high-quality scientific results.

But these days it is not enough to just produce the results, it should be done efficiently. This also means that the instrument must be accessible to those without extensive training.

For an instrument as sophisticated as a STEM, which operates at the limits of not just mechanical and electrical engineering, but also of physics itself, this efficiency and accessibility can be quite a challenge. Several operations have traditionally been done manually and only after extensive training:

-

Instrument adjustments and alignments

-

Synchronization of the microscope and all its detectors

-

Selection of parameters for acquisition and data analysis

TENSOR was created with a primary emphasis on results, efficiency, and accessibility.

This is accomplished with a combination of expert systems automation, advanced scientific algorithms, and cutting-edge user experience design. This level of software automation is only possible with hardware design that is optimized for automated operation, with high-speed, accurate and reproducible control and complete encapsulation of the electron optical behavior.

But it’s not enough just to be able to automate some operations, it must also be possible to automate all operations and to do so in seconds, not minutes. TENSOR was designed from the ground up to do this.

Navigate anywhere on the specimen within seconds

Much of the time during instrument operation is centered around locating areas of the specimen where measurements are performed. This is traditionally done with a very complicated manipulation of knobs, joysticks, and buttons while watching a live image. TENSOR shows an image of the entire specimen, and lets you pan, scroll and zoom on that image to navigate anywhere on the specimen within seconds. And similarly, tilting the specimen is done by interacting with the diffraction pattern while TENSOR keeps the specimen centered.

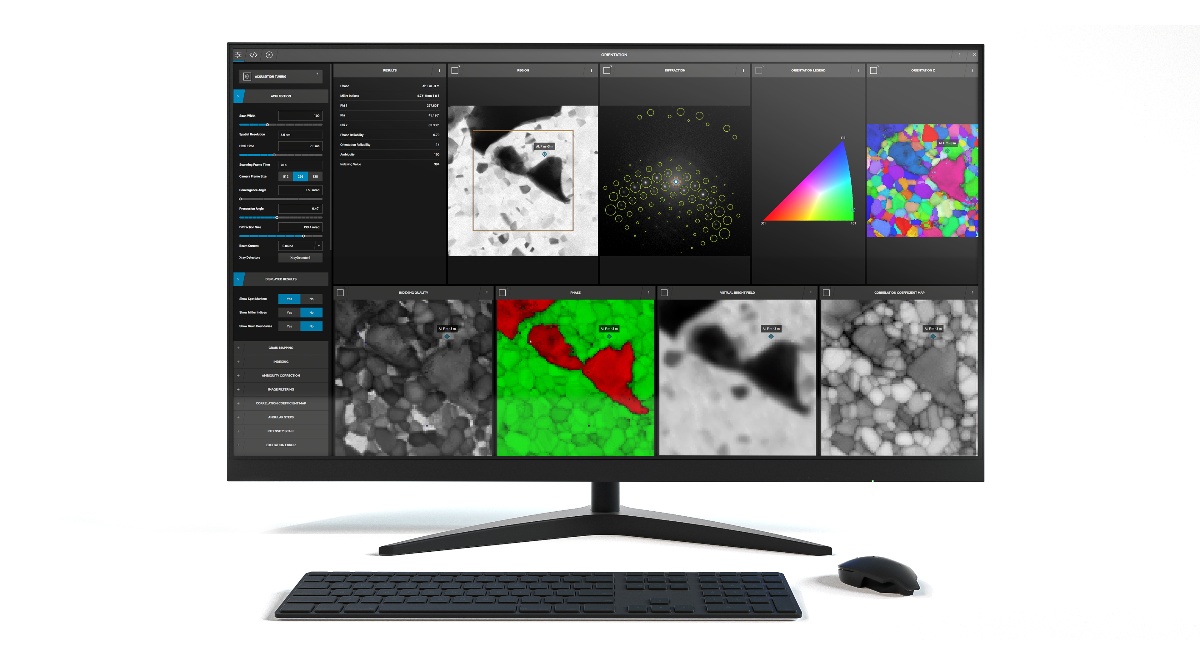

Advanced STEM measurements for near-real-time results

TENSOR doesn’t stop at aligning the instrument, but helps users get the best results as quickly as possible. There are a wide variety of out-of-the-box measurements designed by scientists with decades of STEM applications experience.

Each measurement puts the instrument into the optimum electron optical state, helps the user select the best acquisition parameters, and adjusts the instrument to get the best resolution and signal quality. And most measurements have built-in analysis for near-real-time results, even for complex analyses like diffraction orientation and phase mapping or quantitative EDS mapping.

All these components of TENSOR design allow users to get meaningful results within minutes of loading their specimen. Equally important, new users can get those results the first time they use TENSOR.

Simple, fast ROI Screening and Selection.

Quickly screen and select regions of interests (ROIs) from a large, up to 2x2mm, digital overview image. Image tiles are acquired automatically at the beginning of each work session, without changing the microscope illumination mode, leveraging class-leading field of view at low STEM imaging magnifications. A benefit of this implementation is that samples are not exposed to unnecessary electron dose for in-session navigation purposes, as the overview image is acquired only once.

Choose freely and quickly between Precession ON or OFF.

Optical parameters are automatically adjusted when switching between measurements, including e.g., beam current, beam convergence angle and camera length. No in-depth training is required for notoriously difficult column adjustment and alignment routines, allowing users to spend their time interacting with the specimen, not the optics. Other setups, such as electron beam precession, can simply be switched on or off, with user input into parameters such as precession angle and fine-tuning precession pivot point, which is possible thanks to the very high precession frequency.

Tilt to a zone axis.

Automation further aids users in complicated in-session tasks, including tilting the specimen to a zone axis selected by the user, for measurements such as strain, or imaging of defects such as stacking faults and dislocations.

Ready to discuss TESCAN TENSOR?

Please get in touch today.

Our global team will be available to answer questions about the TESCAN line of TENSOR solutions.