Powering Advanced

Battery Technology and

Research with TESCAN

Solutions

Driving Breakthroughs in Lithium-Ion Battery Development & Production

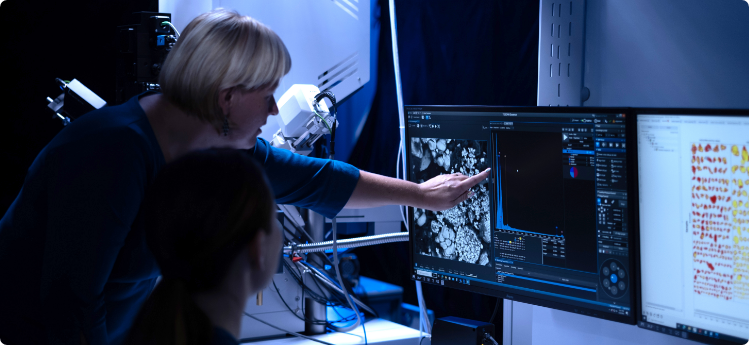

Explore the full potential of lithium-ion battery technology and set new standards for energy and power density in the battery market together with TESCAN. With our electron microscopy, image analysis, and X-ray micro-CT solutions, your battery development can focus on energy efficiency, safety, and eco-friendliness. Our goal: to boost your research and development of new batteries, and optimize manufacturing quality for battery production with the right solutions, proven by experts from academia and industry.

So, join us in navigating the realm of battery innovation and redefining the future of energy storage with TESCAN — your catalyst for battery technology advancements.

Pioneering Successes in Battery Development

“At Dragonfly Energy, our goal is to deliver a more sustainable and cost-effective Li-ion battery, and these metrics are fundamentally defined by dynamic nanoscale interactions occurring inside the cell. TESCAN’s electron microscopy and micro-CT solutions provide valuable, correlative insights into the behavior of these complex systems which enable the development of our innovative cell chemistries.”

Dr. Denis Phares, CEO at Dragonfly Energy

Tackle Development and Quality Assurance across

the Battery Value Chain

Validating Quality of Battery Cells and Modules

- Achieve peak battery cell performance and lifespan, using TESCAN micro-CT for non-destructive electrode analysis.

- Detect electrode cracking and delamination quickly and comprehensively.

- Enhance battery cell performance with TESCAN's detailed quality control and root cause failure analysis.

Optimizing Raw Materials and Recycling Processes

- Enhance the yield of Li, Co, and Ni with TESCAN’s TIMA for better battery recycling and raw material processing.

- Identify and quantify valuable elements and phases in recycled materials.

- Achieve accurate mineral and elemental phase identification for better battery component recognition.

TESCAN Solutions for Battery Development

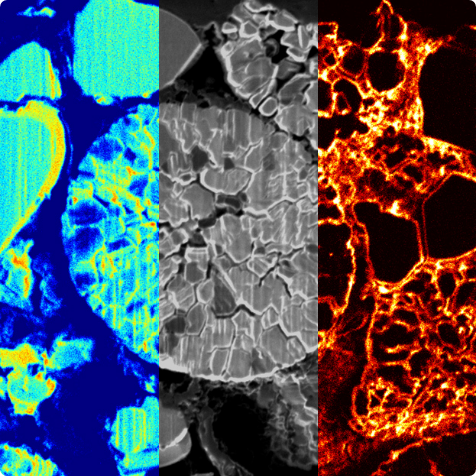

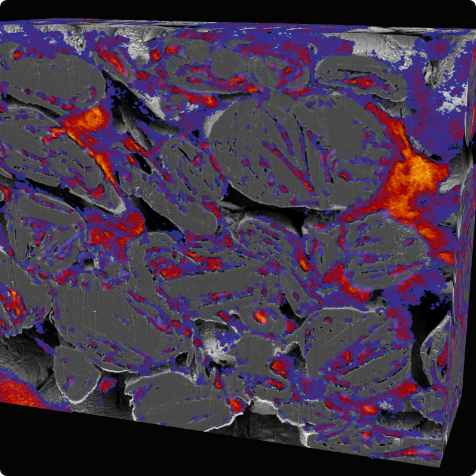

TESCAN AMBER X Plasma FIB-SEM

Achieve unmatched insights into your battery components, driving performance improvements and innovation.

- Enhance battery performance with electrode and separator characterization.

- Promote innovation through chemical analysis of battery components.

- Use 3D tomography and chemical analysis for detailed battery insights.

TESCAN CLARA UHR SEM

Boost failure analysis and your understanding of component morphology at the nanoscale with TESCAN CLARA UHR SEM.

- Boost quality assurance through battery material evaluation.

- Detect impurities affecting battery properties.

- Use SEM, EDS, and Raman spectroscopy for structural analysis.

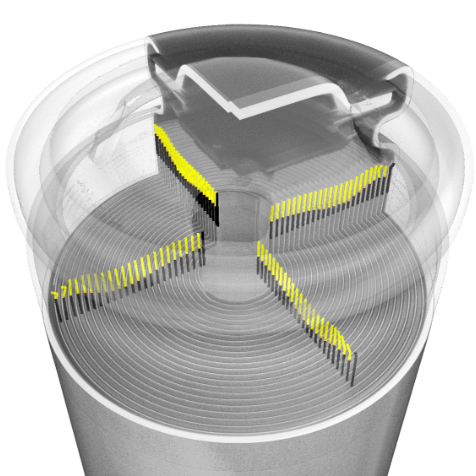

TESCAN UniTOM micro-CT

Perform non-destructive, multiscale lithium-ion battery characterization with TESCAN UniTOM micro-CT, ensuring thorough materials quality control.

- Improve Quality Assurance in midstream/downstream battery operations.

- Use multiscale 3D analysis for insights into battery materials.

- Detect electrode issues and contaminations.

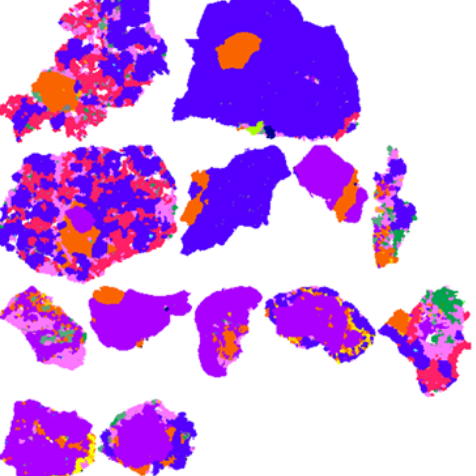

TESCAN TIMA

Use TESCAN TIMA to enhance yield of Li, Co, and Ni from ore or recycled materials, promoting efficient and cost effective raw materials delivery.

- Increase yield of Li, Co, and Ni in mining operations.

- Gain textural insights from thermo-mechanically processed black mass.

- Extract elemental information from spent lithium-ion batteries.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.