Boost Battery

Performance with

TESCAN AMBER X

for Multiscale Material

Investigation

Get 2D and 3D Access to the Internal Structures and Chemistry of Battery Materials

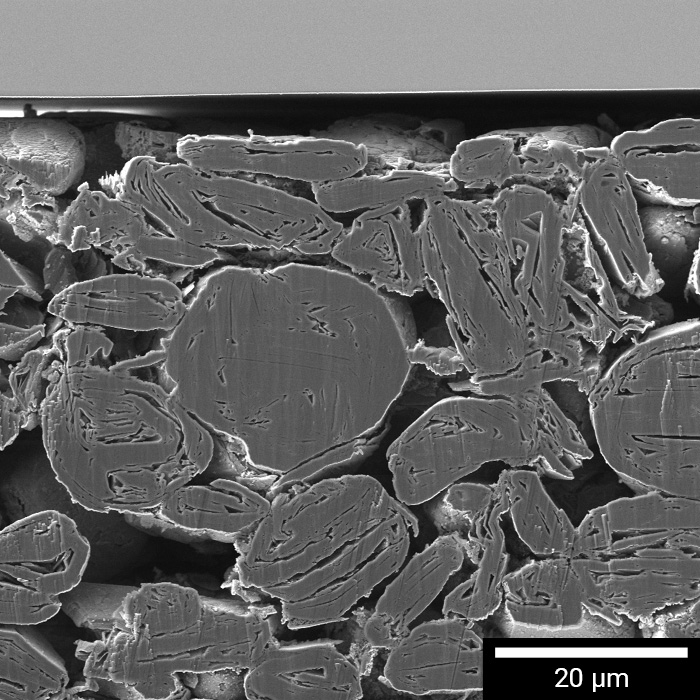

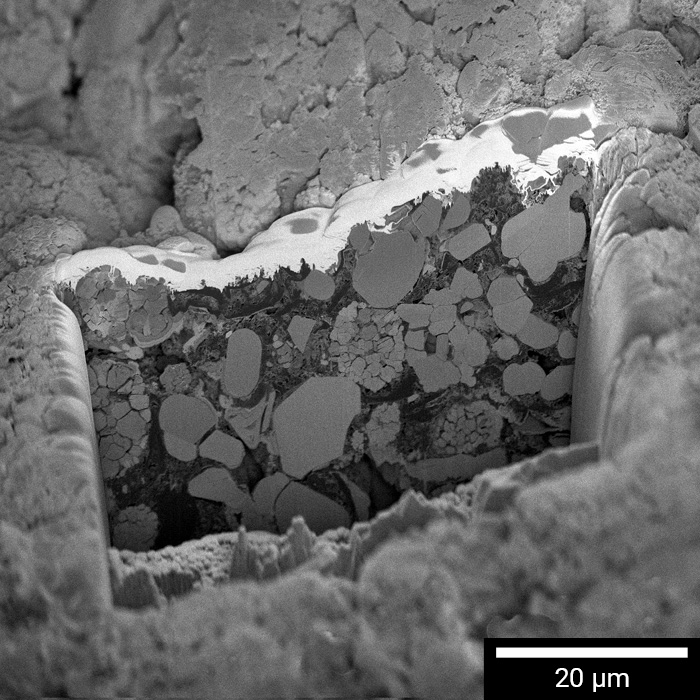

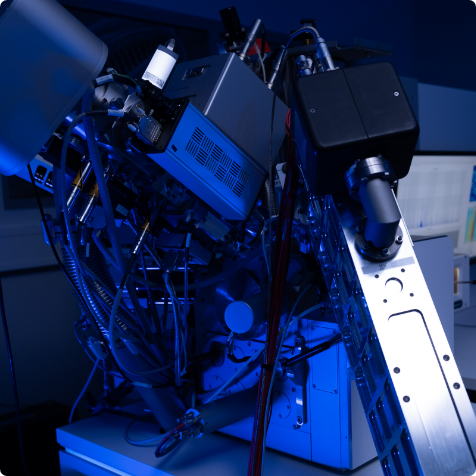

TESCAN AMBER X UHR Plasma FIB-SEM offers 2D and 3D access to the internal structures and chemistry of battery materials, driving materials research, leading to remarkable battery performance improvements. Experience high-resolution observation with the state-of-the-art BrightBeam™ SEM column and expedite subsurface analysis using market leading, highest throughput Xe plasma FIB technology.

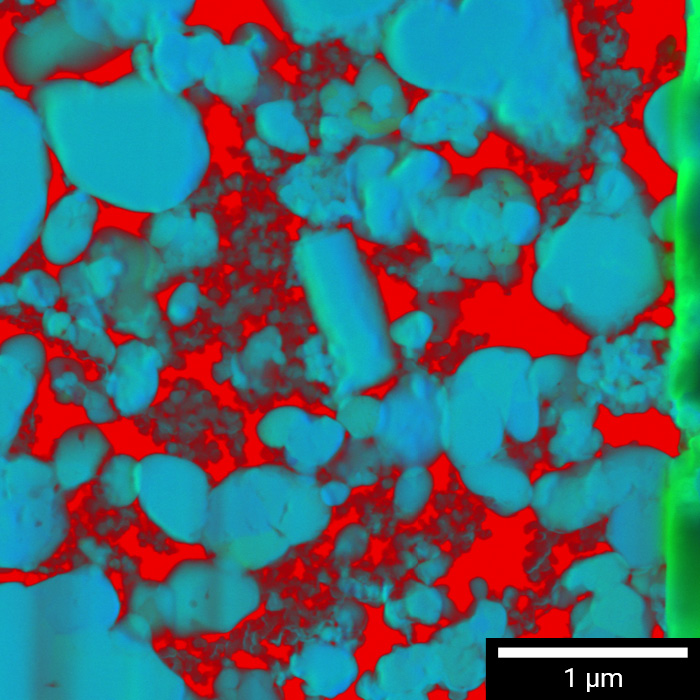

With powerful electron and elemental detection capabilities, easily analyze and visualize topography, material, and chemistry, regardless of your sample's characteristics. In a single system, benefit from comprehensive 2D and 3D analytical capabilities for multimodal characterization of battery materials, ranging from mm-scale to nanoscale.

How TESCAN AMBER X Empowers Your Research

Comprehensive

Volume Characterization

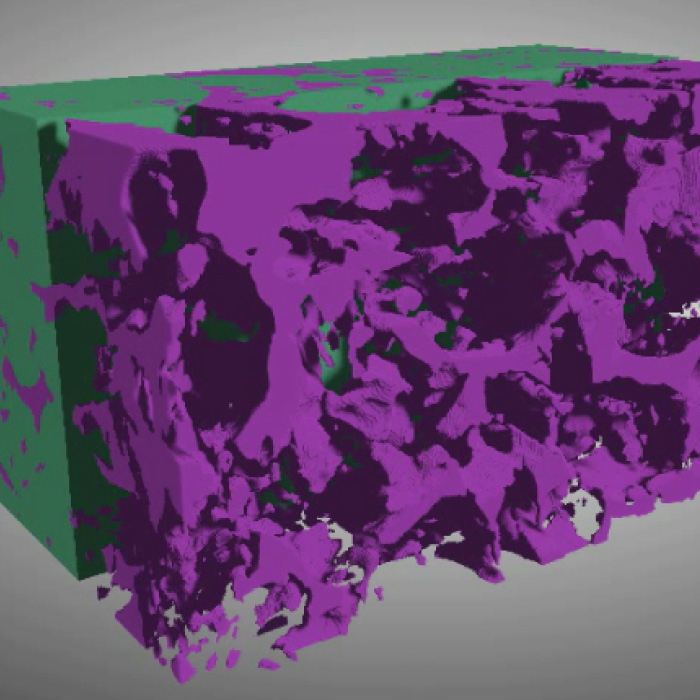

Obtain multimodal insights through large volume analytical (EDS/EBSD/ToF-SIMS) tomography.

Light Element Detection

Explore distribution of the lightest elements, including lithium.

Large Area FIB Processing

Attain comprehensive data by characterizing millimeter-scale cross-sections.

High Level

of Automation

Maximize instrument time for efficient analyses.

Easy

to Use

Simplify your research process with user-friendly controls.

Sensitive

Sample Protection

Safeguard Li containing samples against air or moisture.

The Main Benefits

of TESCAN AMBER X

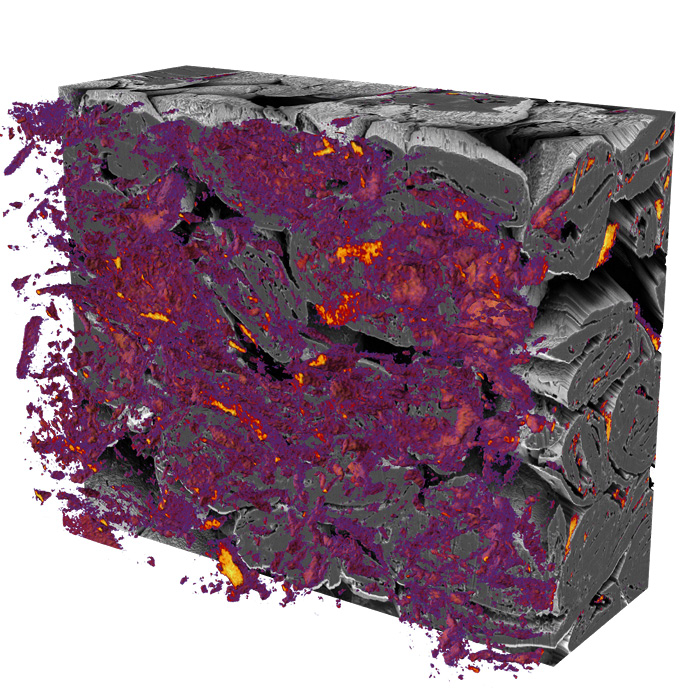

- Improve Battery Lifespan and (Dis)Charge Rate by Gaining Insights into Solid Electrolyte Interface (SEI) Properties:

Explore distribution, homogeneity, thickness, and chemical composition of SEI using ToF-SIMS, enabling high surface sensitivity and detection of the lightest elements, including lithium. - Assure Maximum Battery Component Quality:

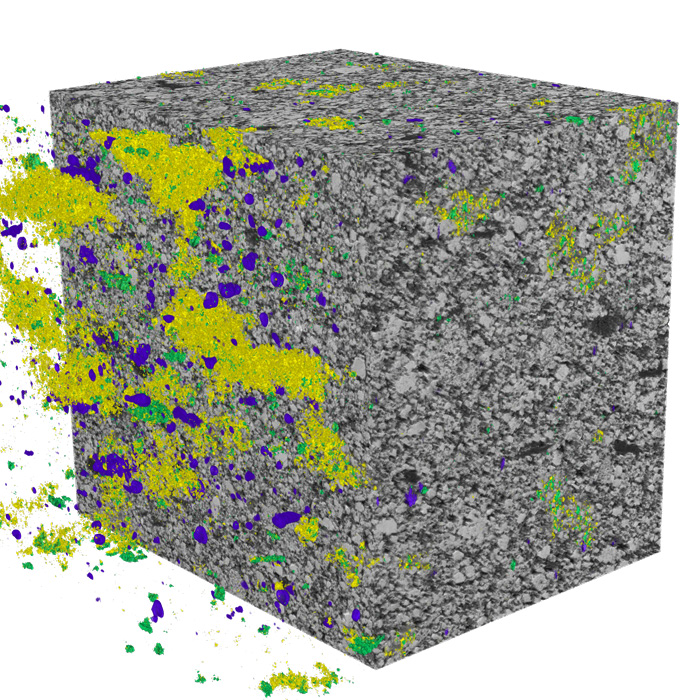

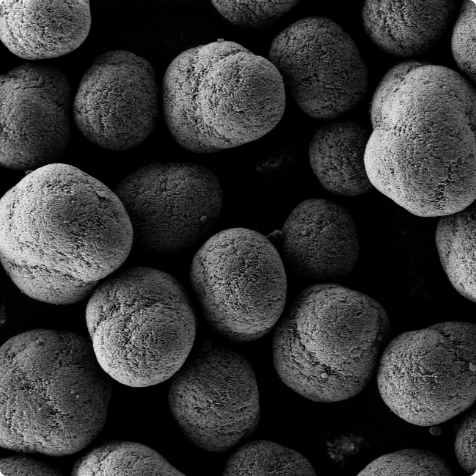

Analyze the chemical and structural homogeneity of electrode materials. Study the volume distribution of particles, binder, carbon black, and porosity through 3D tomography, using SEM, EDS, and ToF-SIMS data collection.

- Prevent Battery Capacity Fade through High-Resolution Study of electrode and Cathode Particle Degradation Mechanisms:

Utilize SEM and STEM imaging, ToF-SIMS, and Raman spectroscopy to understand electrode particle degradation. - Assure Targeted Battery Lifespan by Identification of Chemical Contaminants in Electrodes:

Use SEM, EDS, and/or ToF-SIMS techniques for 2D or 3D materials analysis. - Optimize and Precisely Characterize the Chemistry of Your Cycled and Lithium Containing Battery Materials by Assuring Inert Gas (oxygen and moisture-free) Environment:

Protect sensitive samples against air or moisture with inert gas transfer.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.

.png?width=476&height=476&name=Learn%20more%20about%20screenshot%20(4).png)