In-depth Characterization of Battery Active Materials and Components with Multiscale and Multimodal Applications

Advanced Characterization of Battery Active Materials

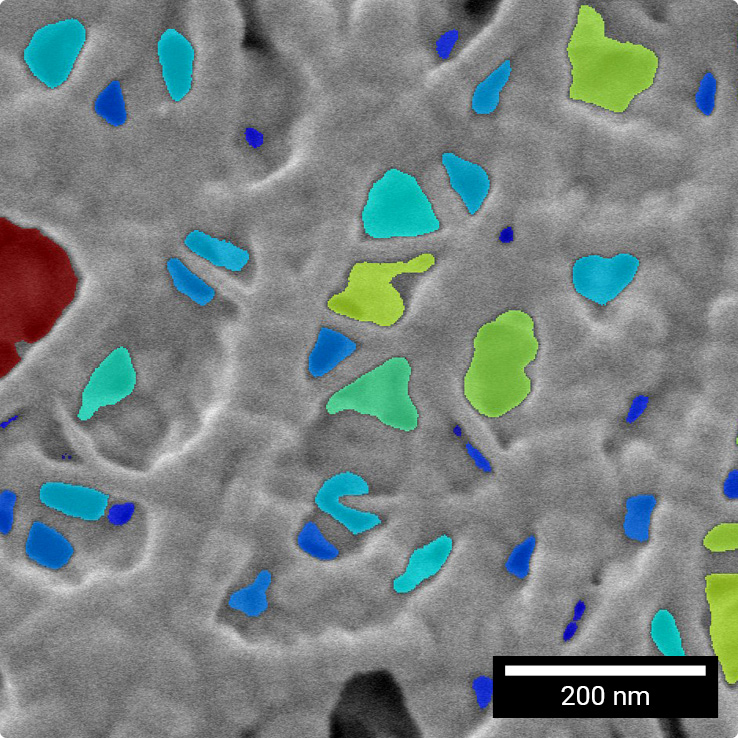

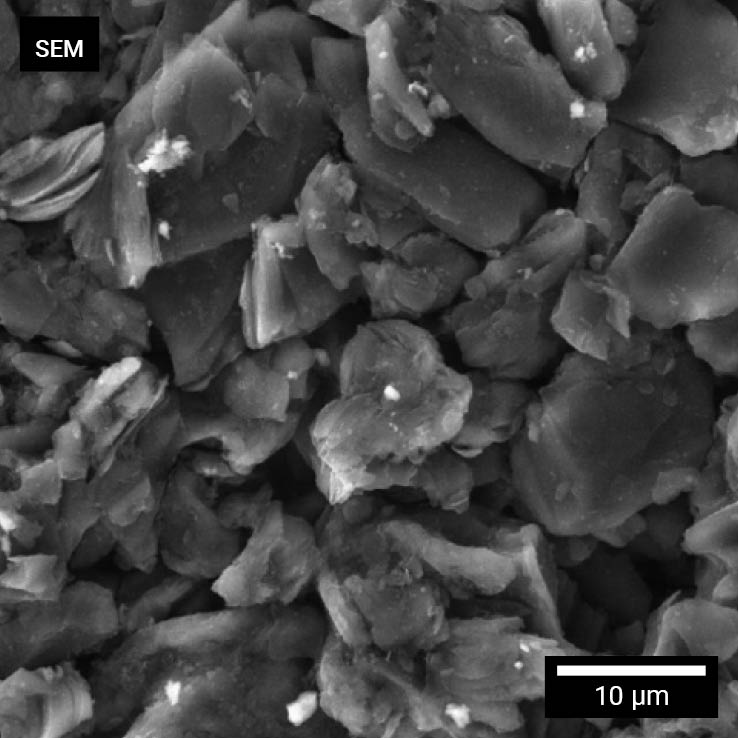

Graphite and lithium metal oxide particles are typical fundamental parts of lithium-ion battery electrodes. Understanding the geometric attributes and the chemical and structural composition of these active materials is pivotal for optimal battery performance. Consistent characterization of battery active materials during production ensures uniform battery cell quality.

High-resolution SEM observation is a powerful tool for the characterization of battery active materials in the form of particles. It reveals their essential properties such as size, shape, and defects. In this section, we showcase rapid data acquisition, image segmentation, and subsequent processing to derive insights into NMC particle dimensions.

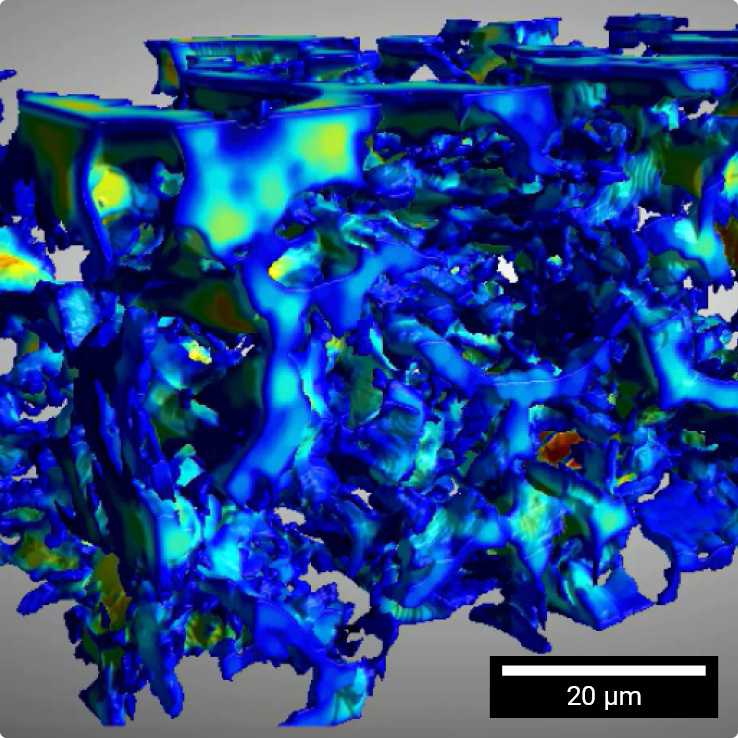

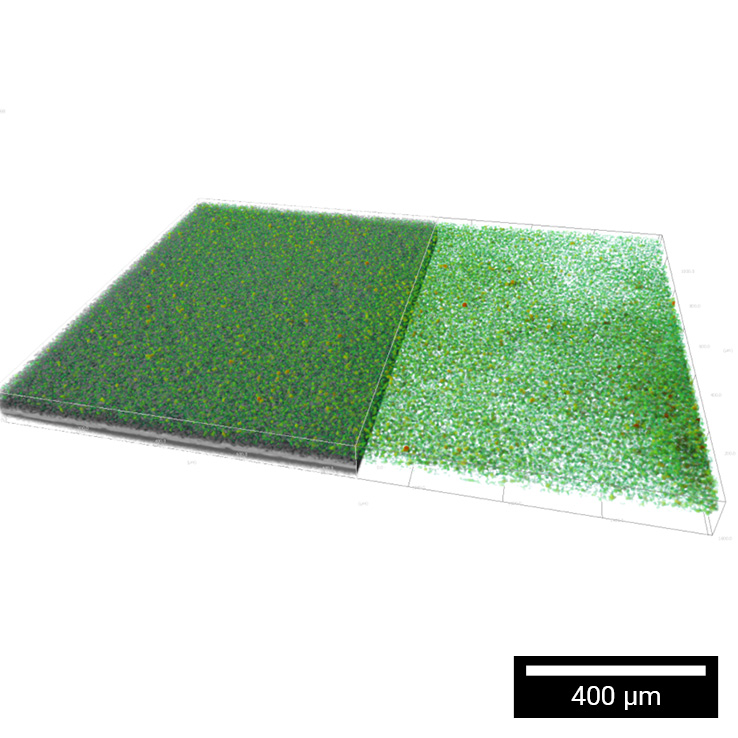

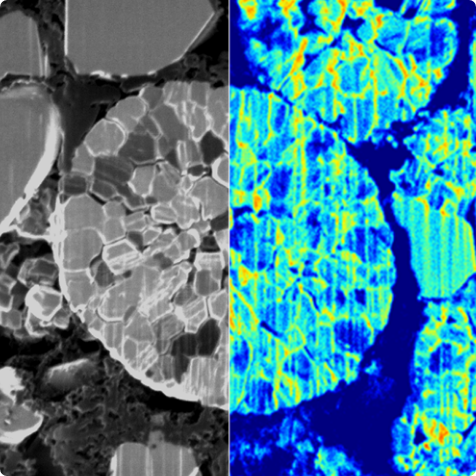

Porosity Analysis in Battery Components

Material porosity is a defining factor in the characterization of electrodes and separators as battery components. It's the ratio of void volume to the total volume and it plays a significant role in battery cell performance. The porosity and interconnectedness of pores in the electrode affect factors like energy density and lithium mobility. Well-balanced electrode porosity minimizes unnecessary weight and costs from excess electrolyte. Separator porosity impacts mechanical stability and is vital for lithium movement during cycling.

For comprehensive characterization of battery component porosity, SEM observation combined with image segmentation is employed. For analysis with even greater detail, 3D FIB-SEM tomography or X-ray microtomography is used to investigate volume porosity.

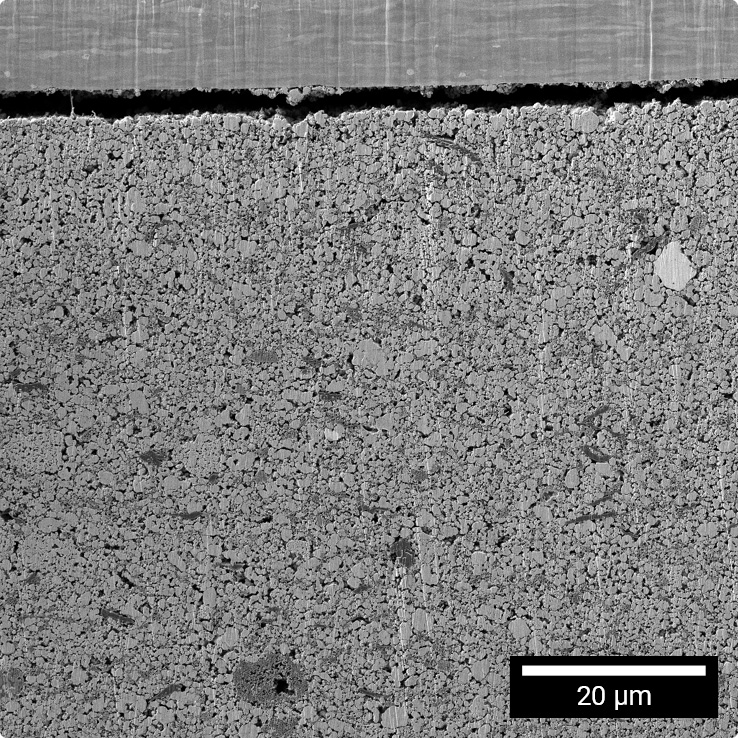

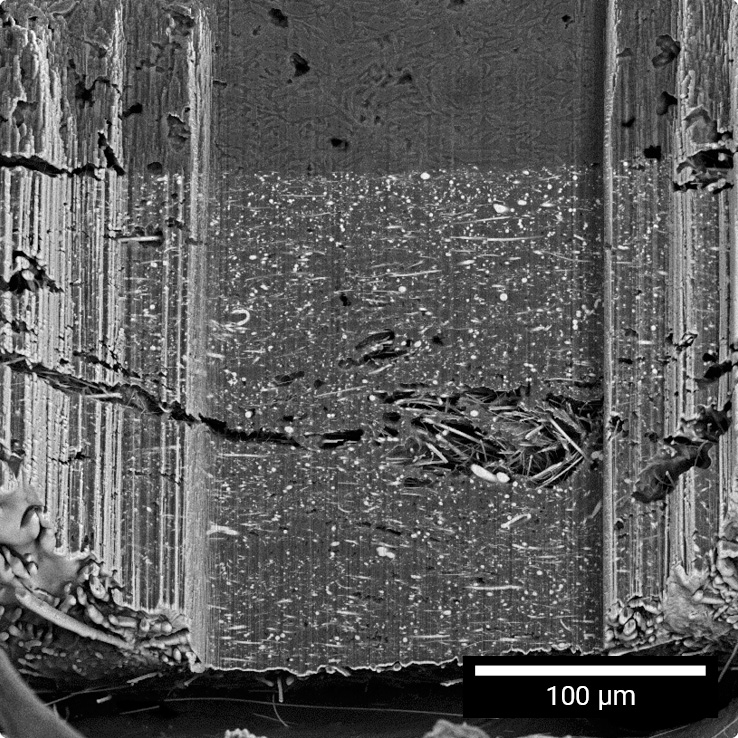

Detecting Electrode Delamination and Solid-State Electrolyte Cracking

Delamination and cracking in battery materials arise from production or cycling processes and can affect battery lifespan and capacity. Delamination often results from weak adhesion between the electrode and the current collector, while cracking in solid-state electrolytes is due to volume changes during cycling.

Our FIB-SEM system offers a detailed view into delamination and cracking, allowing for precise characterization of battery components. This system can identify areas with these defects using high-resolution SEM observation.

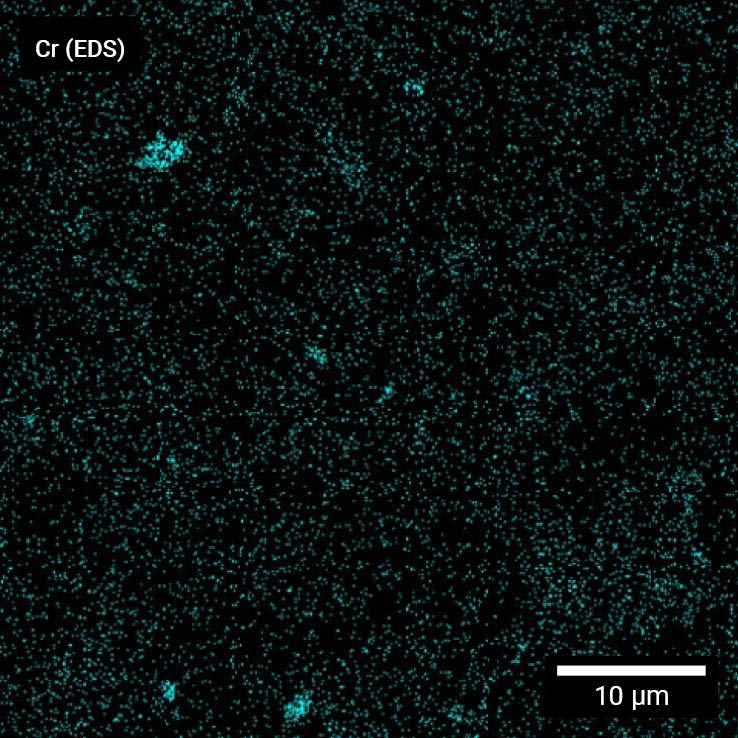

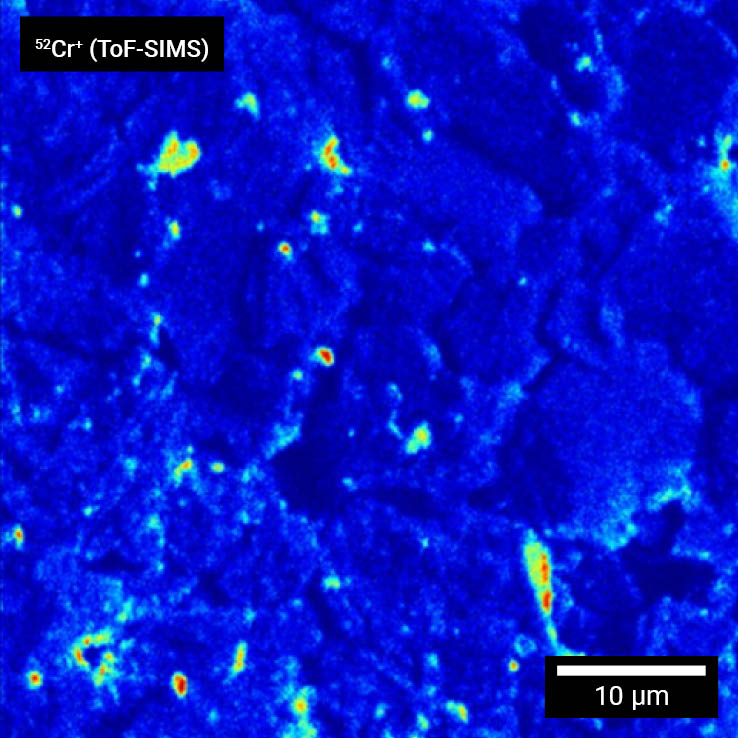

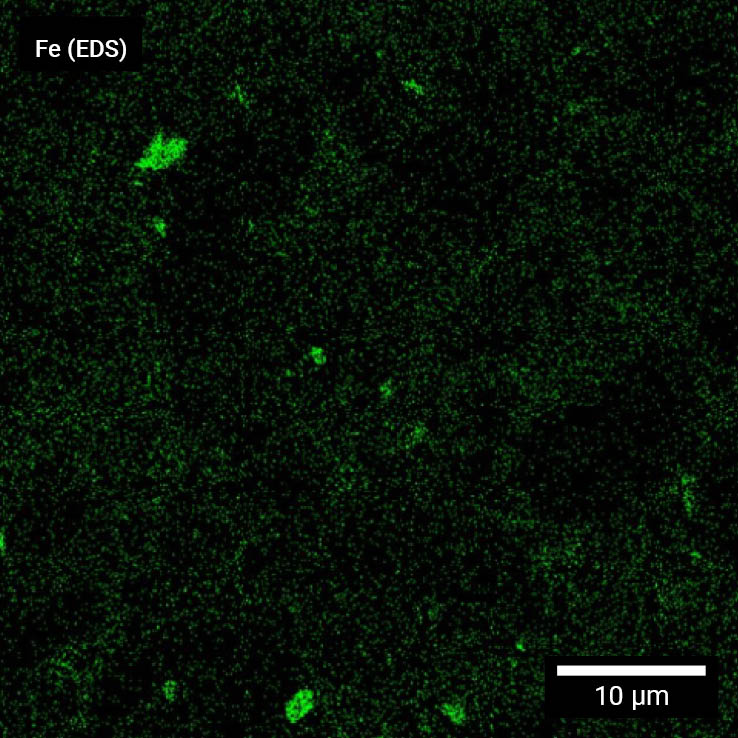

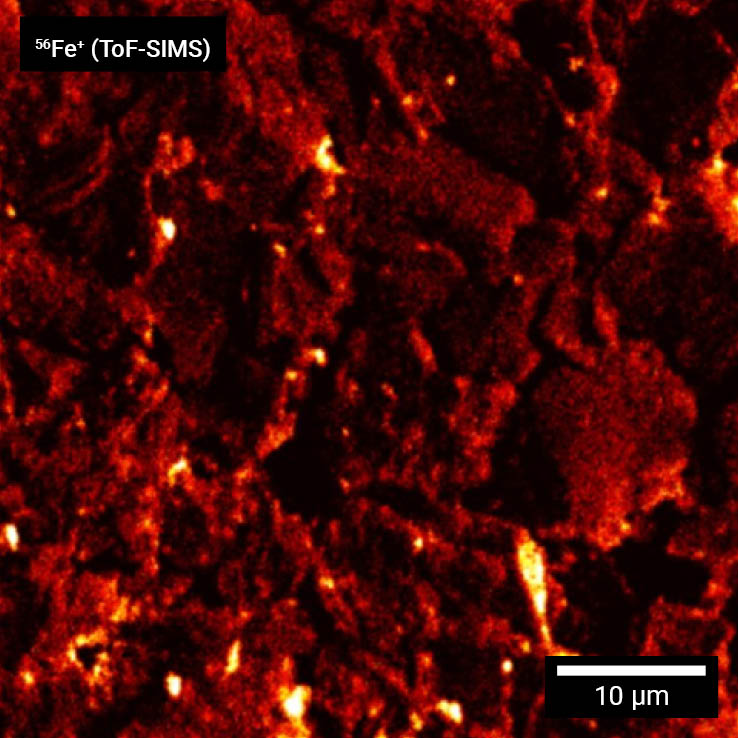

Identifying Chemical Contaminants in Battery Active Materials and Components

The presence of chemical contaminants can partially affect battery lifespan and performance. These contaminants, originating from production or raw material processing, can cause parasitical chemical reactions, corrosion, battery material degradation and loss of lithium inventory.

For accurate characterization of battery active materials and components, SEM observation and EDS elemental and/or ToF-SIMS chemical mapping are employed to pinpoint and analyze these contaminants and their effect on battery material degradation.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.