Maximize Battery

Metal Recovery

from Ores and

Secondary Raw

Materials

Understand the Value of Lithium Ores and Minimize Losses during Battery Mineral Processing

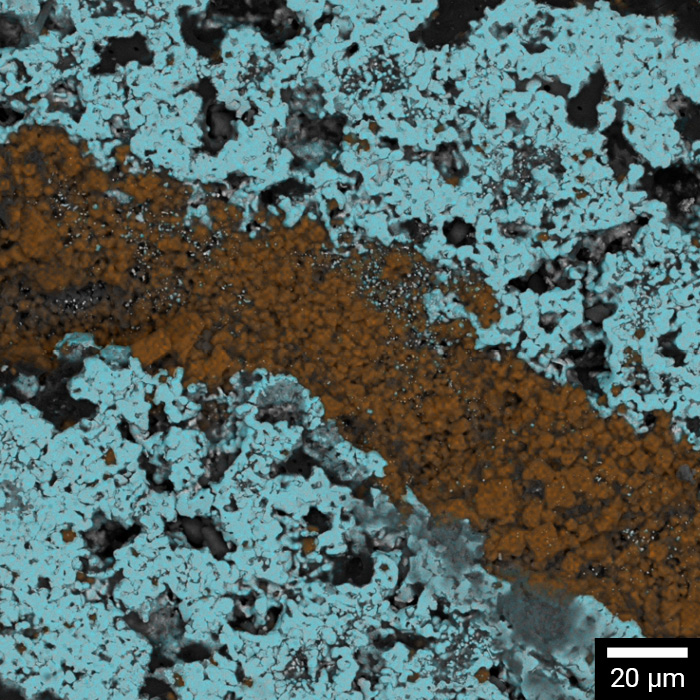

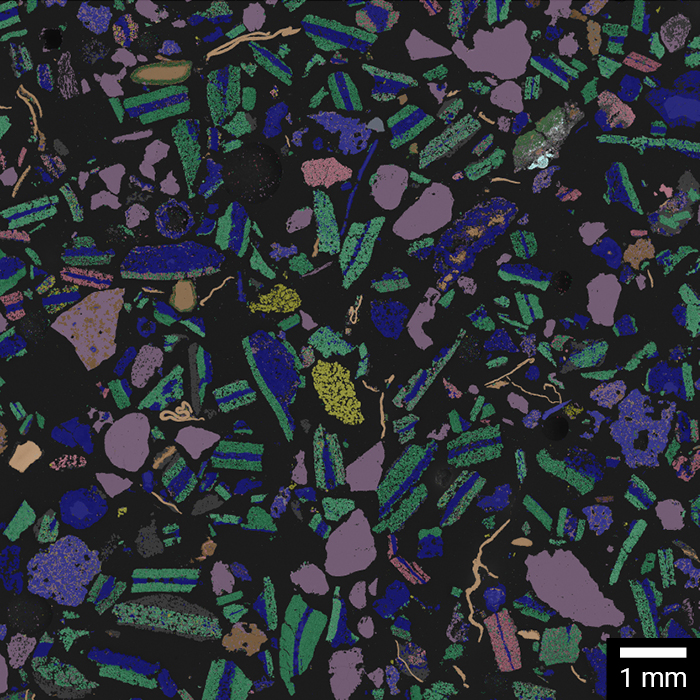

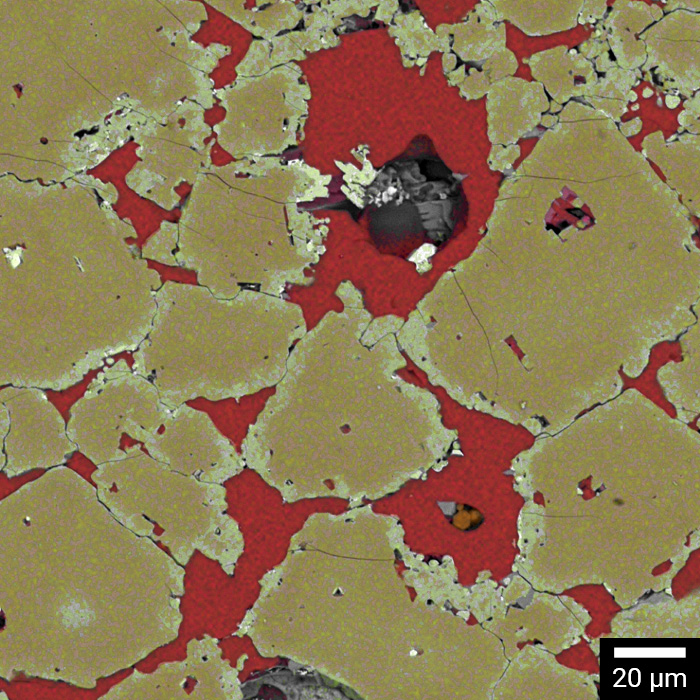

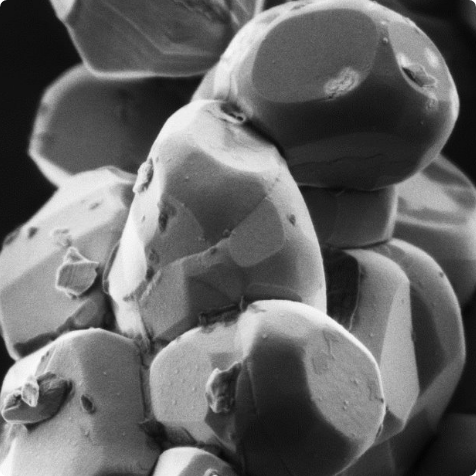

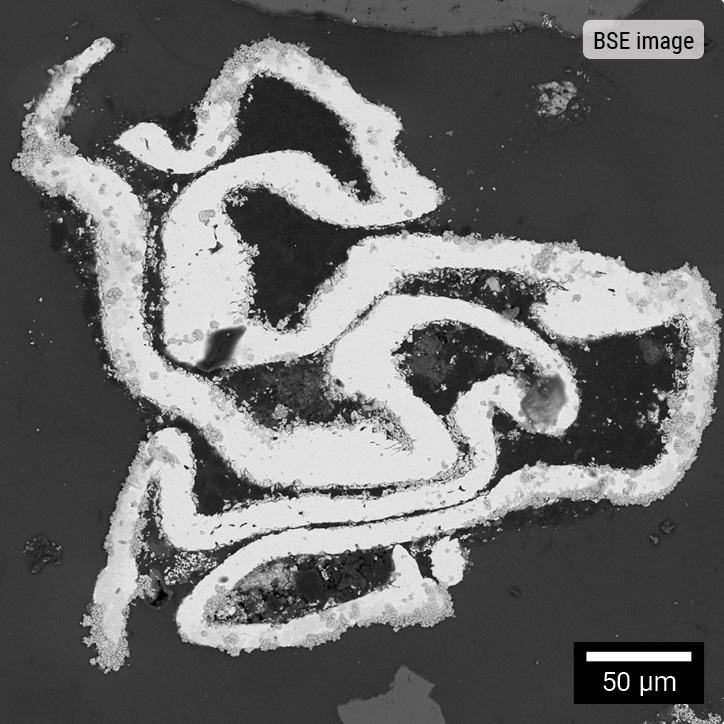

To unlock the value of ore-based battery metals and minimize losses during mineral processing, it is crucial to consider not only the lithium content, but also the ore's amenability to processing. Various minerals such as phosphates (amblygonite or triphilite) and silicates (spodumene, petalite, zinnwaldite) can host lithium, each with unique processing characteristics.

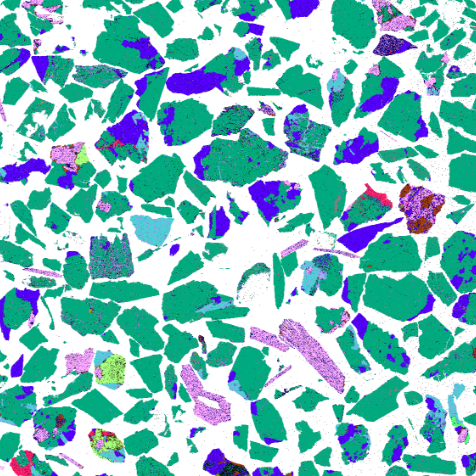

TESCAN TIMA plays a vital role in:

- Determining lithium distribution and guiding selection of the best processing methods like flotation, magnetic, or gravity separation.

- Assessing the liberation degree and grain size distribution through texture analysis, enabling optimization of the target grind size.

- Analyzing processing waste to pinpoint loss origins, and uncover valuable components like tin or tantalum minerals, ensuring the maximum value extraction from raw materials coming from minerals (ores).

TESCAN TIMA: Dependable Elemental Identification for Lithium Minerals

Identifying lithium minerals has always been a challenge due to Li being the lightest metal. Traditional EDS detectors fail to detect lithium. Even windowless EDS detectors have high detection limits, rendering them ineffective for detecting natural lithium minerals.

TESCAN TIMA comes to the rescue with:

- An extensive database of simulated spectra for reliable lithium mineral identification, and the capability to analyze ratios of other elements to pinpoint specific minerals.

- Expertise in understanding diverse mineral compositions, including the varying ratios in spodumene, and detecting lithium in various mineral substitutions.

- Indirect quantification of lithium content using stoichiometric calculations and the option to integrate a Raman spectroscopy for definitive mineral identification.

Say goodbye to the mystery and embrace the power of TESCAN TIMA to liberate the secrets of lithium minerals.

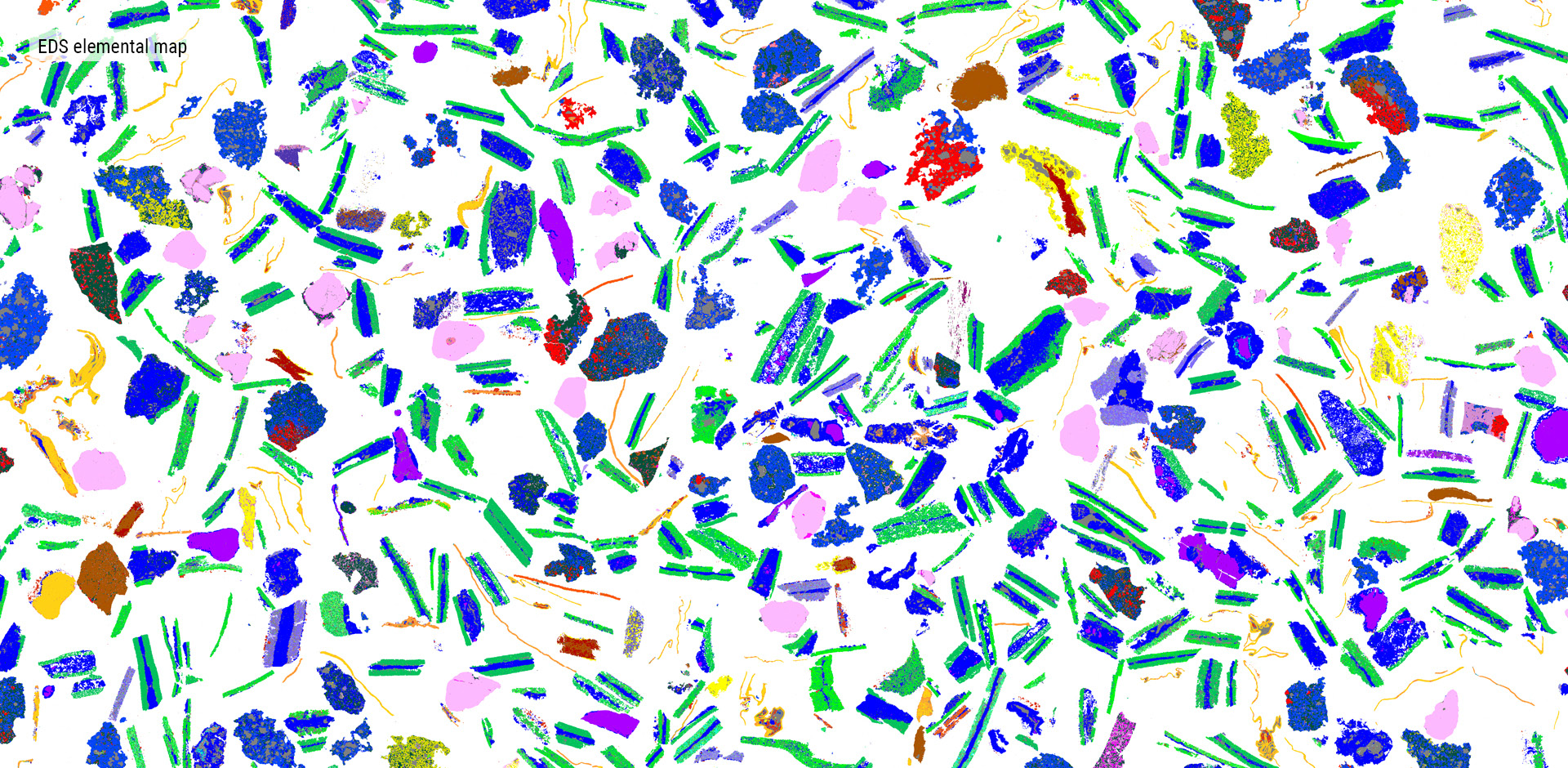

Unveil Battery Metal Components and Unlock the Secrets of Black Mass

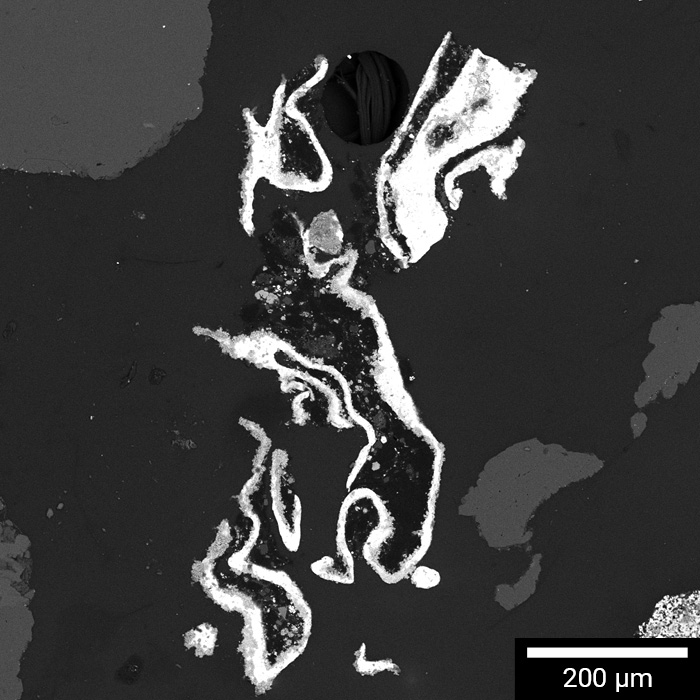

The production of black mass, a crucial step in battery energy transformation, is a complex process influenced by various factors and the wide range of lithium batteries involved.

However, there is a challenge: the resulting mixture of shredded and crushed batteries can be unpredictable, potentially contaminated with unexpected battery types or other waste materials. In some cases, it may not even meet the criteria for black mass.

WITH TESCAN TIMA BATTERY ANALYSIS, YOU WILL BE ABLE TO:

- Uncover detailed black mass characteristics, including particle size, texture, and chemical composition, while categorizing particles by cathode material for precise battery chemistry identification.

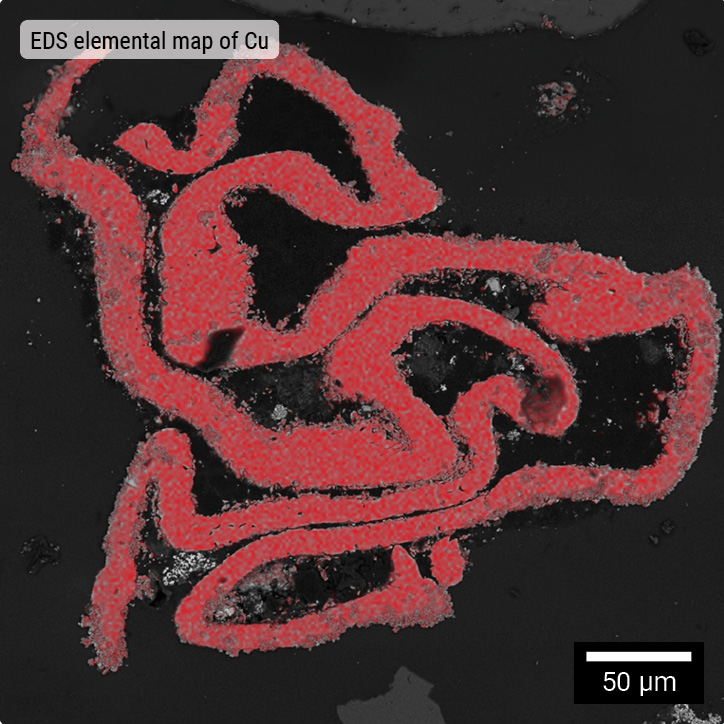

- Accurately quantify various battery types in the final composition and measure diverse components like anodes and charge collectors.

- Streamline and optimize recycling processes by understanding components like graphite and other crucial metallic battery parts.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.