Unleash the Full Potential

of Your Samples

with TESCAN Micro-CT

Systems: UniTOM XL and

UniTOM HR

Discover the most versatile micro-CT systems available in the market, providing exceptional resolution, high throughput, and optimal image quality for multi-scale analysis, from module to electrode.

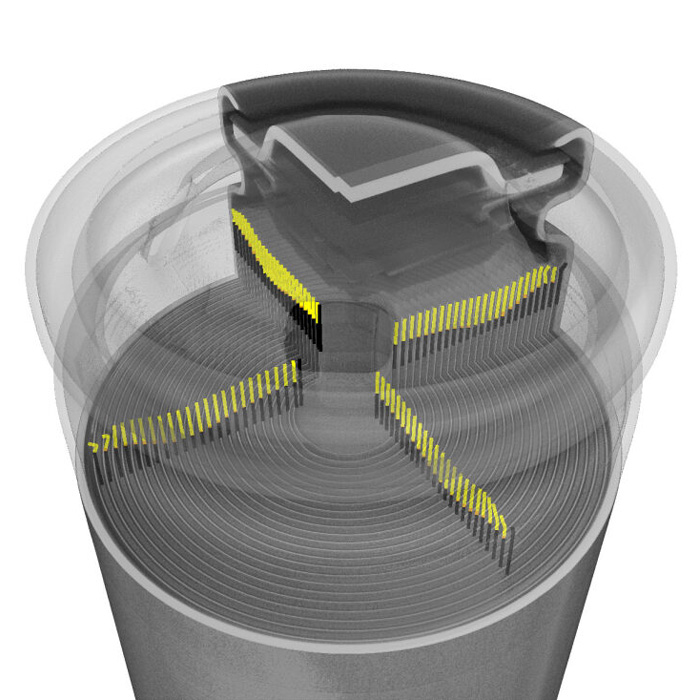

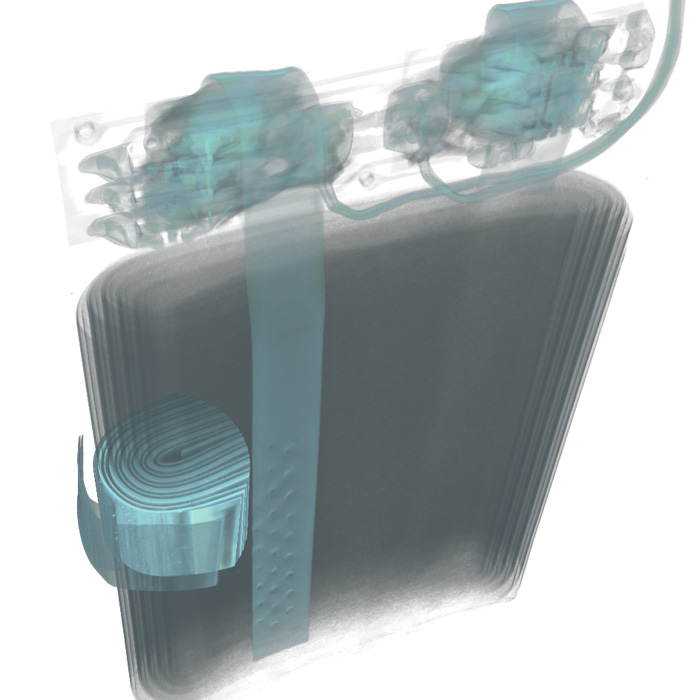

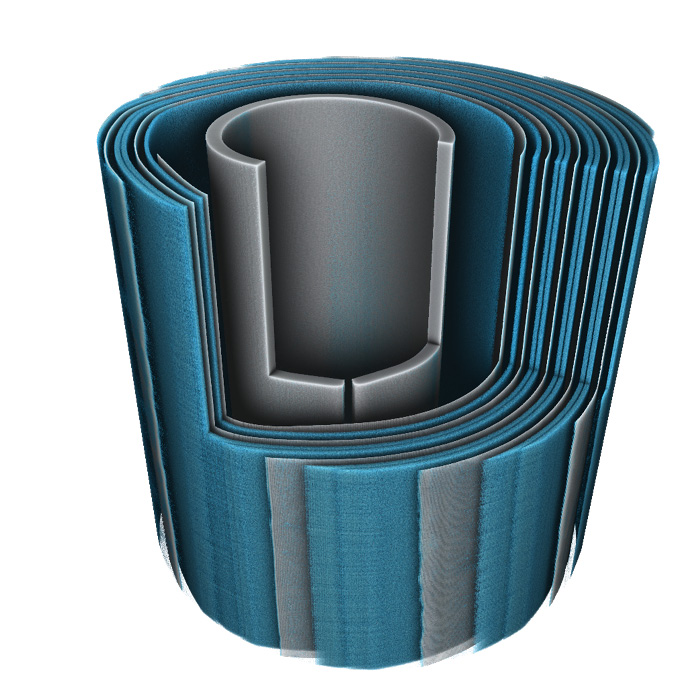

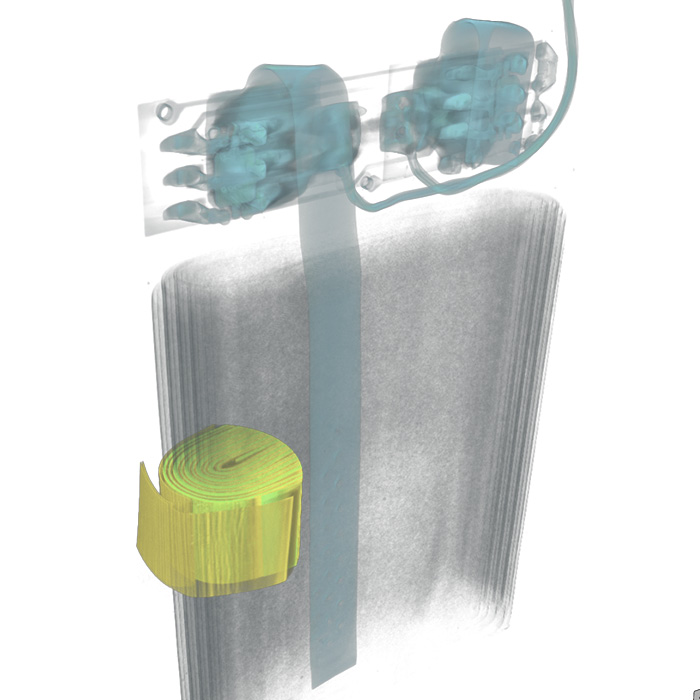

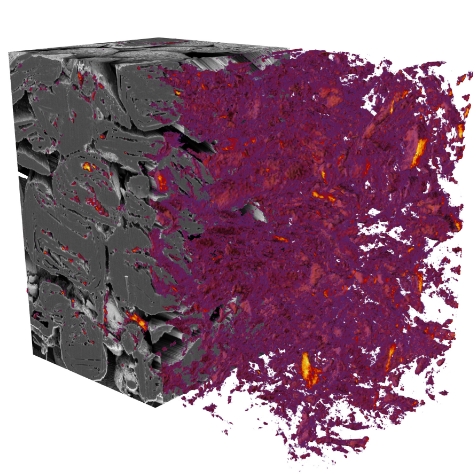

TESCAN's micro-CT systems offer up to 11 degrees of freedom, allowing scanning of large samples using intricate scanning geometries. Our intuitive VOIs™ scanning workflow, informed by overview scans, offers a comprehensive multi-scale approach that delivers insights at both centimeter and micrometer levels.

With high temporal resolution scanning, each scan takes just a few seconds, enabling high throughput scanning of multiple samples. Our systems offer true dynamic micro-CT, allowing real-time and 3D observation of processes - or as we call it, 4D - for unparalleled insights into sample behavior. By optimally integrating all major micro-CT components, we ensure the best image quality in the shortest scan times. This makes micro-CT analysis a crucial step in the TESCAN battery workflow.

Key Benefits of TESCAN Micro-CT Systems

Non-Destructive Characteri-zation

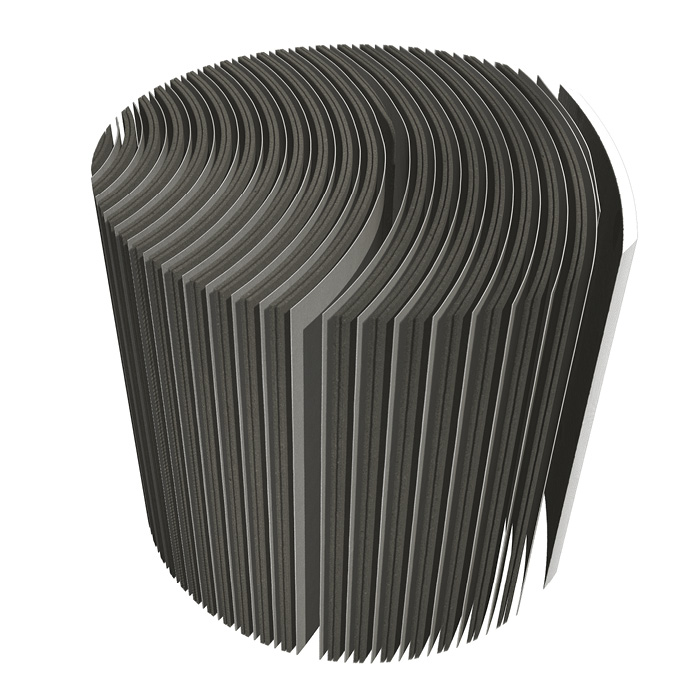

Obtain detailed information about internal structure of the whole batteries in no time.

Comprehen-sive Volume Analysis

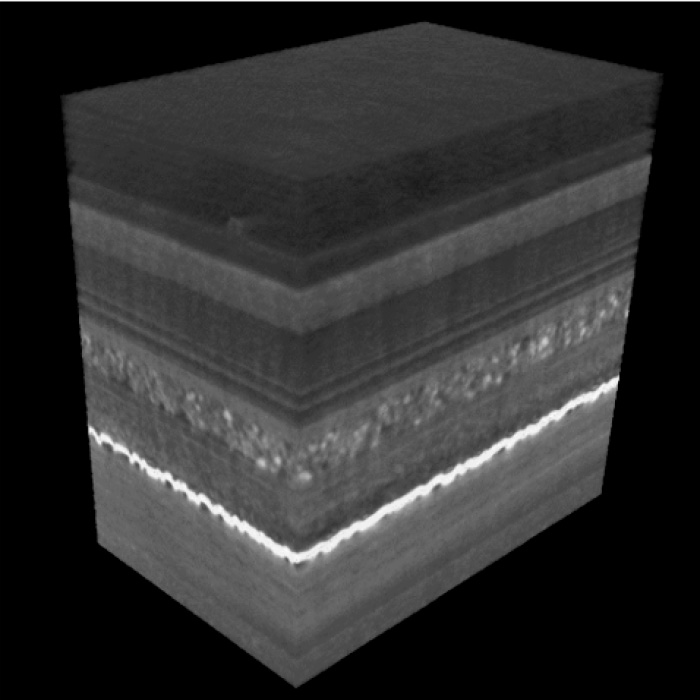

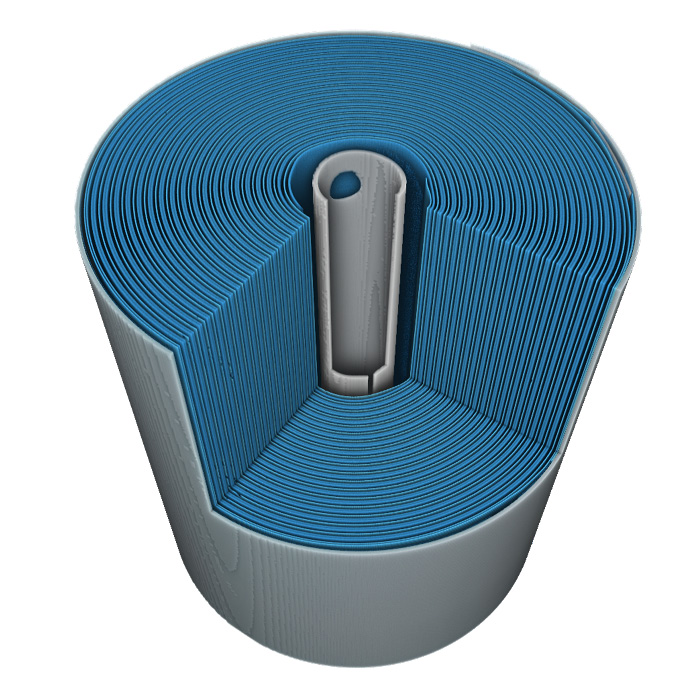

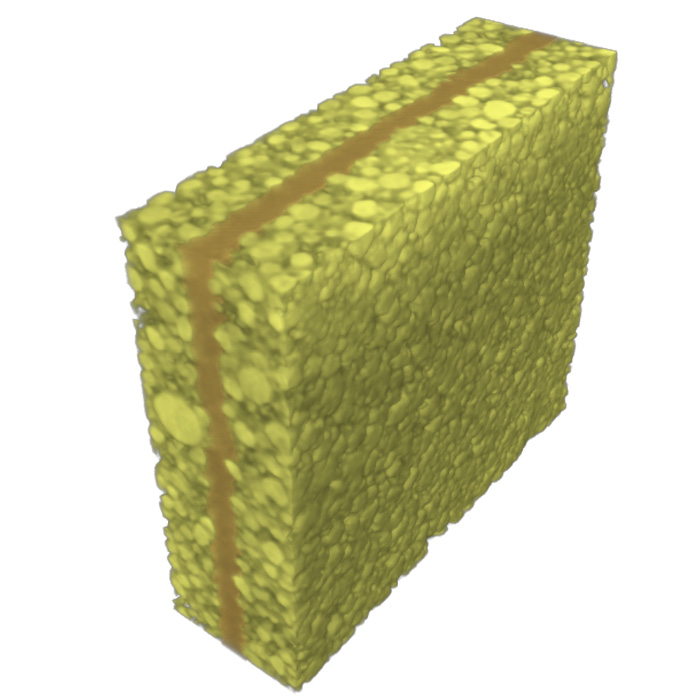

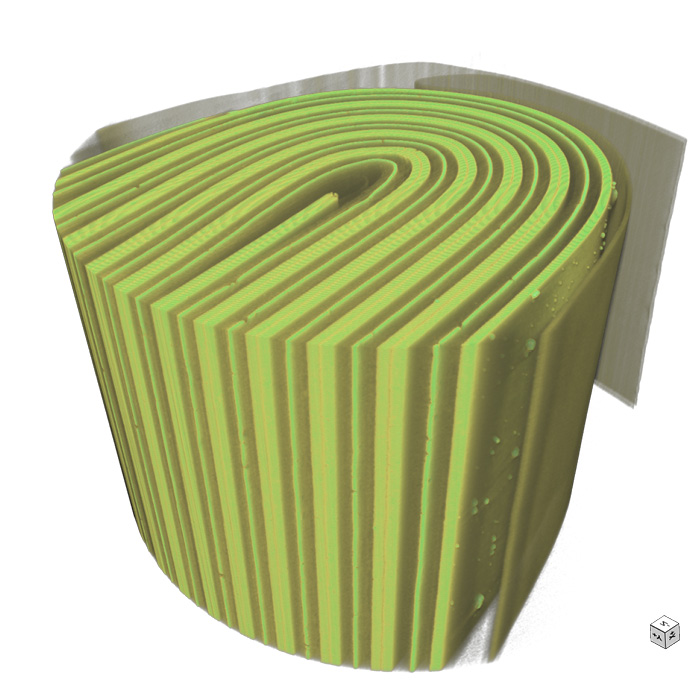

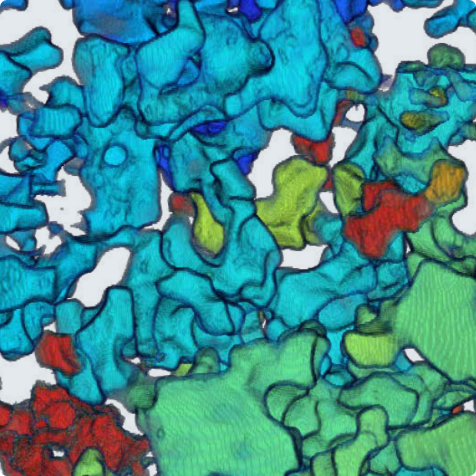

Leverage multi-scale approach that delivers insights at both centimeter and sub-micrometer levels.

Wide

Range

of Samples

Study complete battery systems or single components with maximum throughput.

High-Throughput Analysis

Obtain valuable micro-CT data at unprecedented speed.

User-Friendly Interface

Simplify your data collection process with user-friendly controls.

Multi-Scale VOIs™ Workflow

Make detailed scans only from areas that matter.

Experience the Full Range of Benefits with TESCAN Micro-CT Systems

- Ensure Maximum Battery

Cell Quality:

Quickly perform non-destructive, large-scale inspections of the entire battery after electrode winding/stacking, cell assembly, and electrolyte filling. Examine electrode alignment, overhang, current collector connections, and casing quality. - Prevent Battery Capacity Fade with Defect Detection:

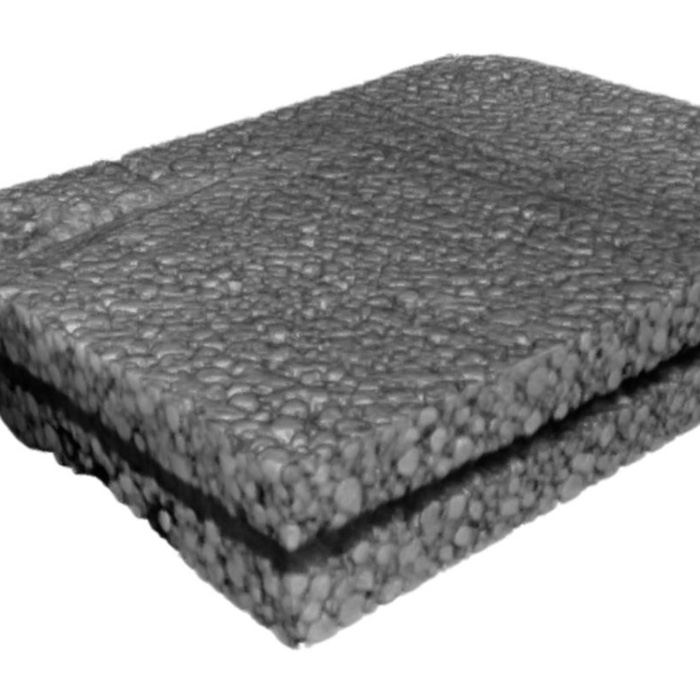

Identify contamination, large-scale voids, cracking, and delamination in assembled and/or cycled cells. Utilize the multi-scale correlative capabilities of TESCAN’s VOIs™ workflow for detailed defect analysis.

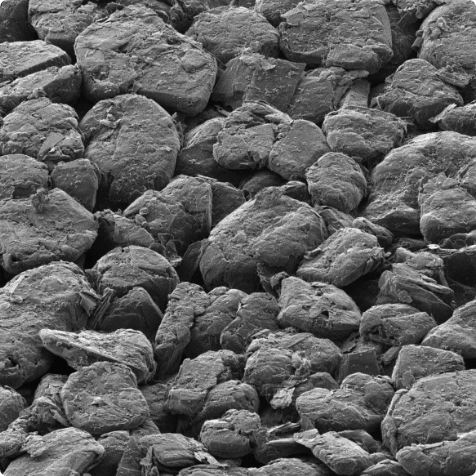

- Enhance Battery Performance:

Conduct sub-micron resolution studies of electrode porosity, interconnectivity, and particle size distribution within mm-scale volumes of battery material. - Support Failure Analysis and Extend Battery Lifespan:

Conduct dynamic in-situ cycling experiments on batteries and monitor physical and degradation processes

in real-time.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.