Preventing Losses in

Battery Metal Recovery

from Ore and Secondary

Raw Materials

Quantify the Efficiency of the Battery Metal Recycling Process through Automated Mineralogy

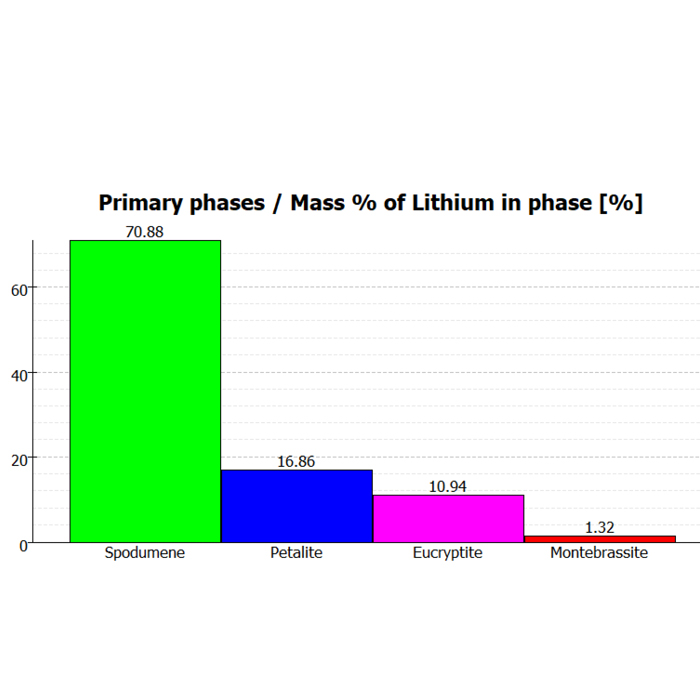

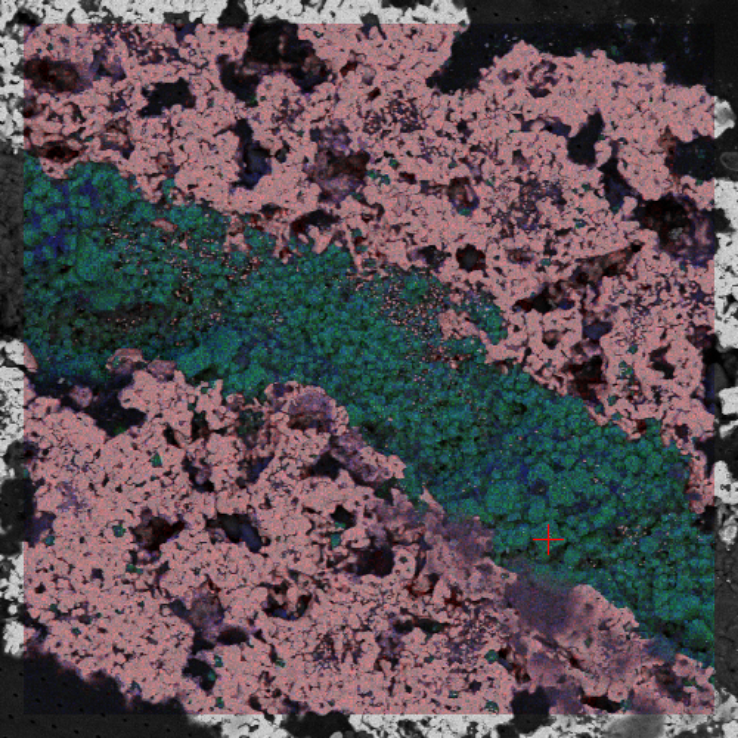

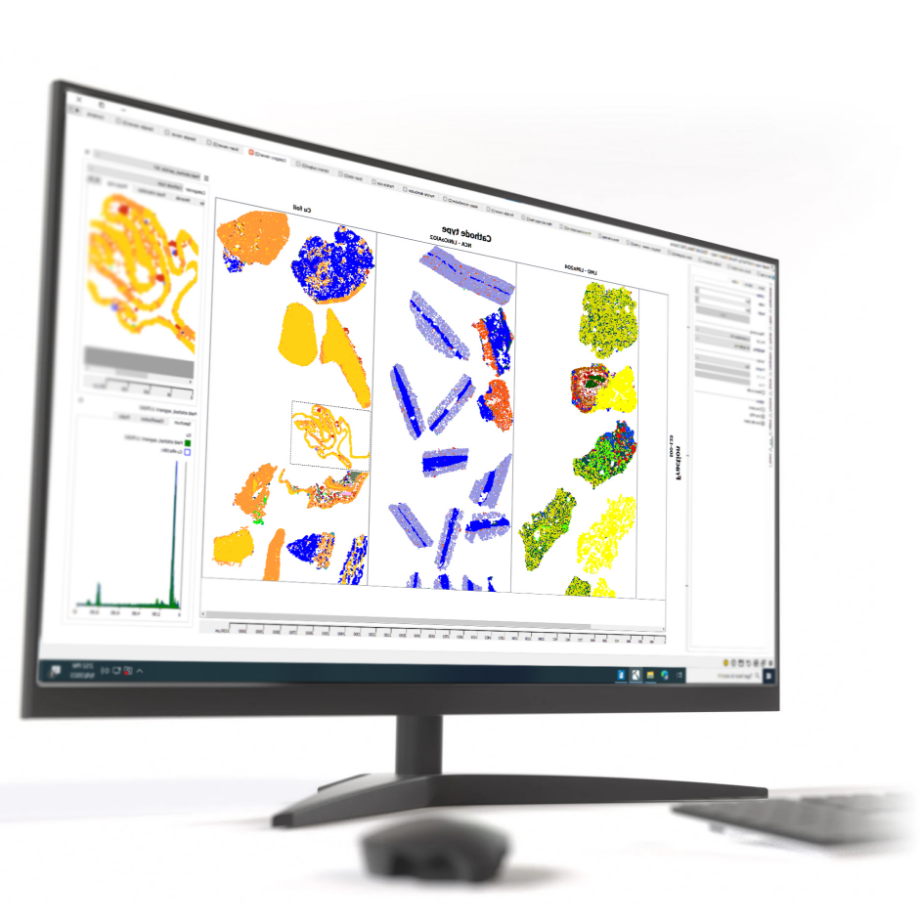

Automated mineralogy is a powerful tool for identifying the causes of element losses during ore beneficiation or recycling processes. TESCAN TIMA (TESCAN INTEGRATED MINERAL ANALYZER) provides valuable insights through elemental deportment, association reports, and liberation degree.

Elemental deportment reveals the phases that host the element of interest, enabling the deployment of specific processing methods. Association reports statistically characterize phases in direct contact with the phase of interest.

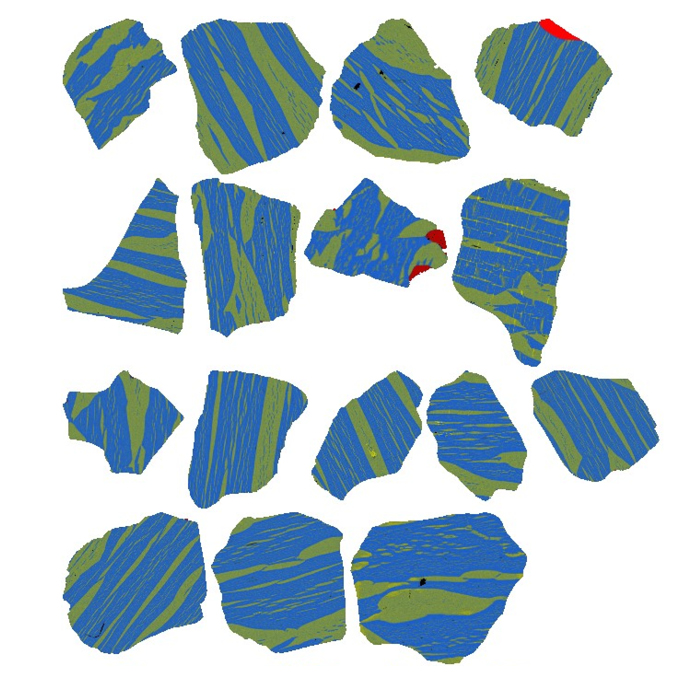

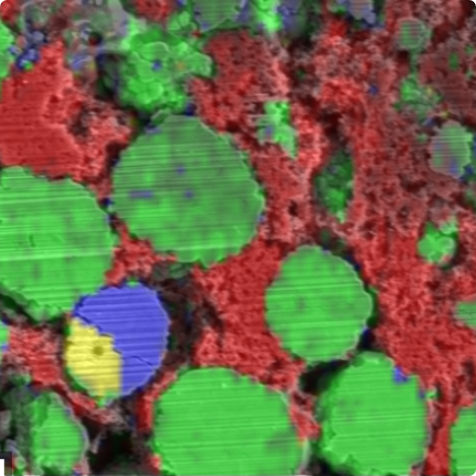

By combining this knowledge with the liberation degree, adjustments can be made to the process, such as finer grinding. Liberation degree is also useful for evaluating the efficiency of delaminating cathode and anode materials from current collectors.

Optimizing the Recovery of Valuable Battery Metals and Elements through Liberation Analysis

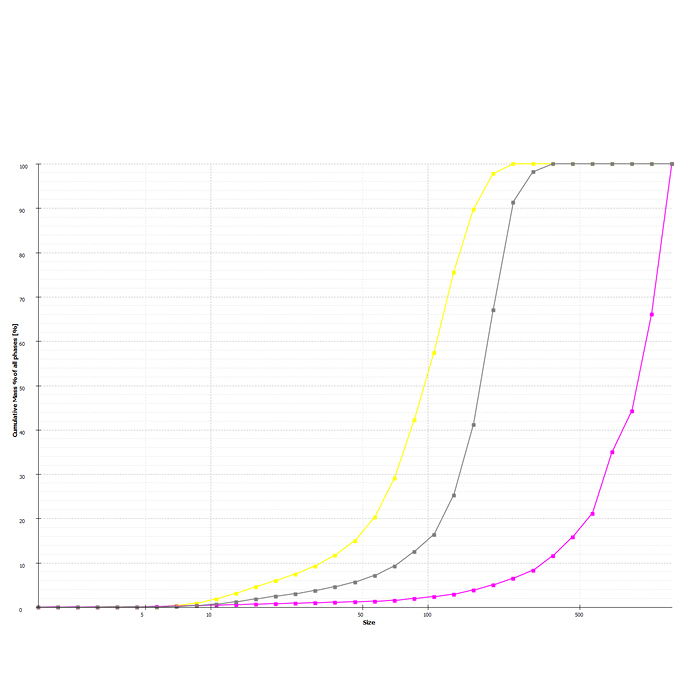

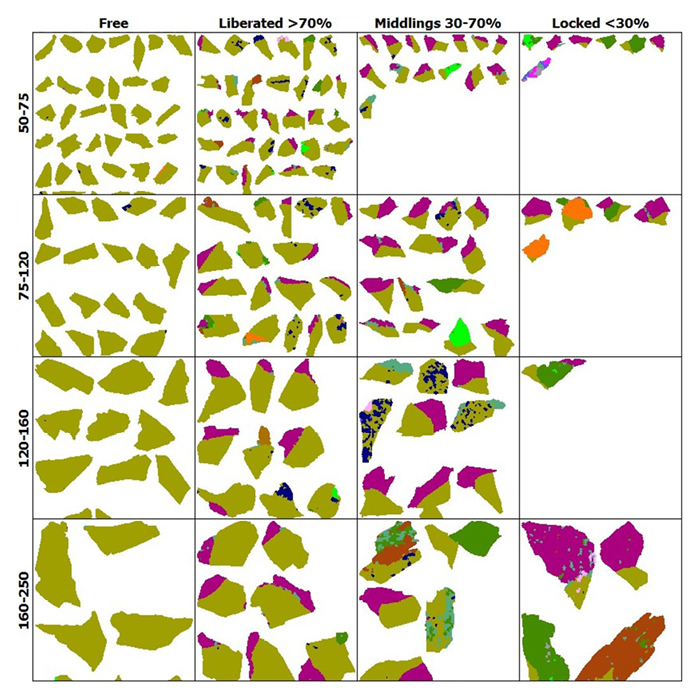

TESCAN TIMA not only provides information on the abundance and distribution of elements and phases but also offers insights into the liberation degree. This textural property describes the exposure of phase of interest during the beneficiation process.

The surface liberation, which represents the percentage of the particle surface formed by the phase of interest, directly affects the probability of the particle reporting to the concentrate during flotation or dissolution during leaching.

On the other hand, the liberation by volume, which represents the volume percentage of the phase of interest forming the particle is more commonly used to predict outcome of electromagnetic and gravity separation.

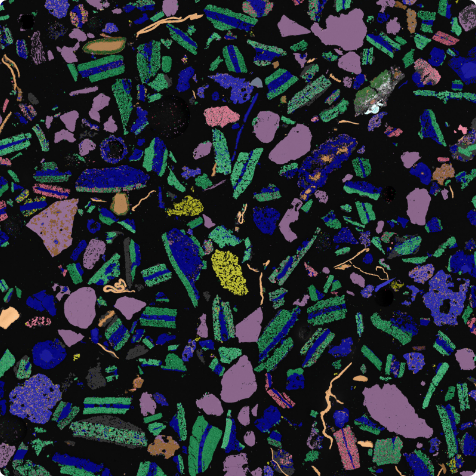

Quantifying Fragments of Different Battery Components in Black Mass

Industrially produced black mass often comes from various sources and contains different cathode materials, such as NMC, NCA, and LFP. Knowing the proportion of these materials is crucial for selecting the appropriate processing method and assessing the value of the black mass.

TIMA effectively categorizes individual battery fragments based on the phases they contain. This phase-based approach is essential since elements like aluminum or iron can be present not just in the active battery components but also in the packaging. Chemical data alone has limited predictive value for black mass evaluation.

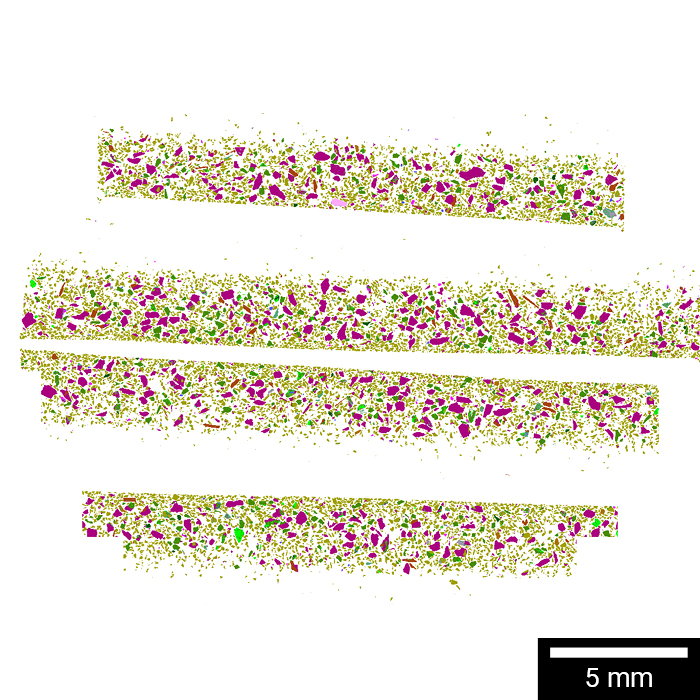

No Need to Choose between Large Area Elemental Maps and High-Quality Spectra

Battery materials, whether primary ore or black mass, are typically coarse-grained. This requires mapping larger parts of the sample or even multiple replicates. Common particle analysis software often forces a trade-off between high-quality spectra and pixel-by-pixel coverage.

However, TIMA employs TESCAN's proprietary technology called spectral summing, which merges spectra from adjacent pixels formed by the same phase. This unique feature enables users to obtain both high-quality spectra and detailed elemental maps from a single run.

Don't Let Analytical Capacity Limit Your Company's Performance in Battery Metal Recovery

Originally developed to meet the needs of the mining industry, TESCAN TIMA excels in analyzing extensive volumes of materials and samples. Its high degree of automation and throughput make it suitable for battery recycling as well.

TESCAN TIMA's exceptional speed is achieved through multiple detectors, smart analytical modes like dot mapping mode, and the spectral summing algorithm. The detectors ensure high throughput and virtually eliminate instrument downtime. Dot mapping mode combined with spectral summing allows reduction of the number of analytical points required, accelerating analysis.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.