TESCAN Applications

for Comprehensive

Characterization

of Materials for New Battery

Technology Development

3D Investigation of New Battery Technology Material Structure and Chemistry

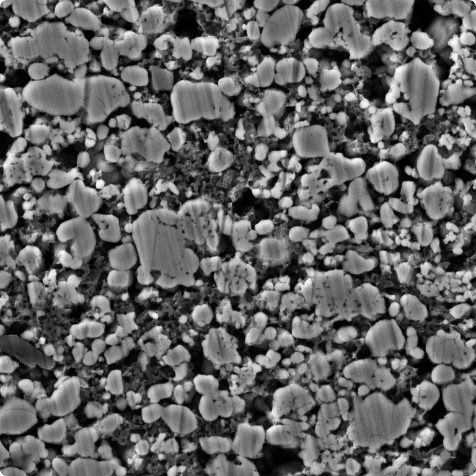

Understanding the structure and chemical composition of battery materials is pivotal to determining the behavior and stability of new battery chemistries during the cycling process. Grasping the complex relationship between local morphology and chemical state, such as particle, void, lithium, and binder distribution within electrodes, is vital for performance optimization and degradation resistance for these advanced battery materials.

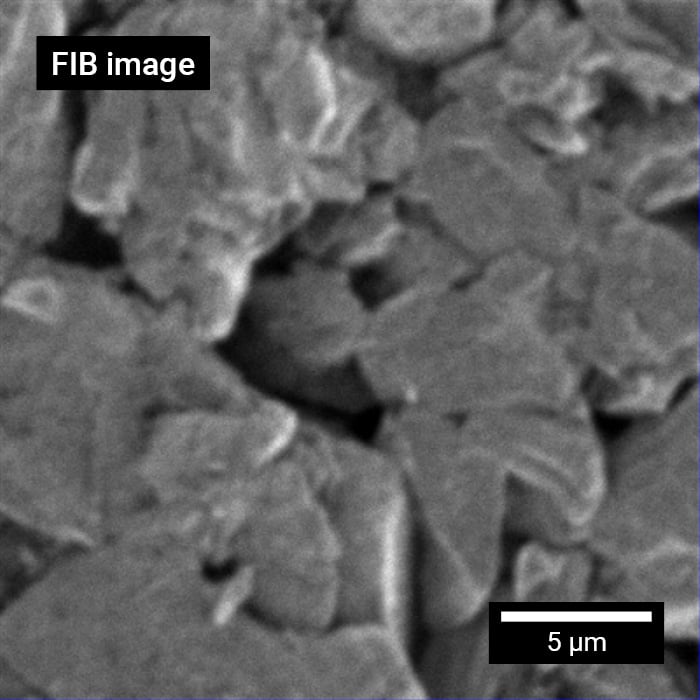

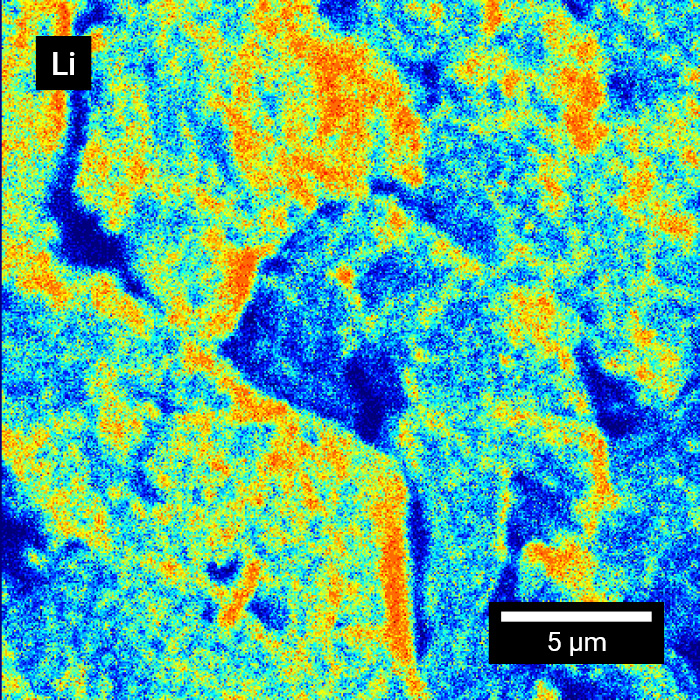

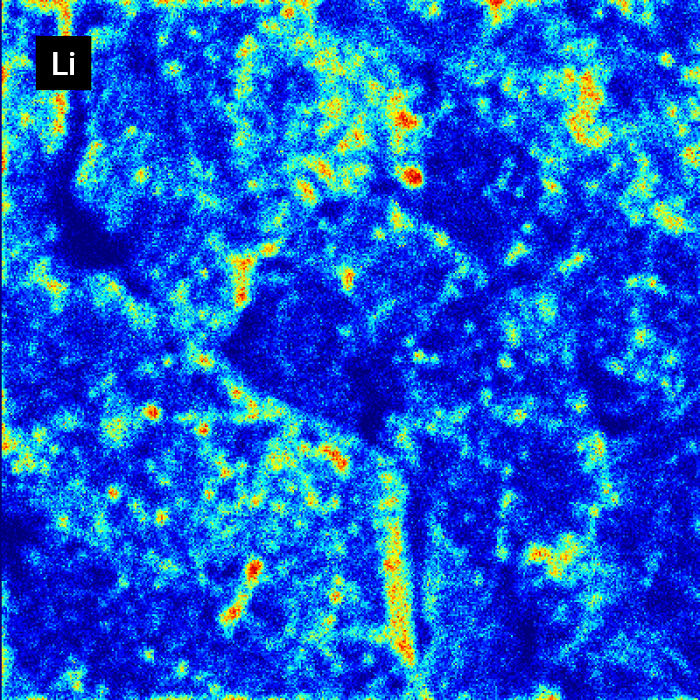

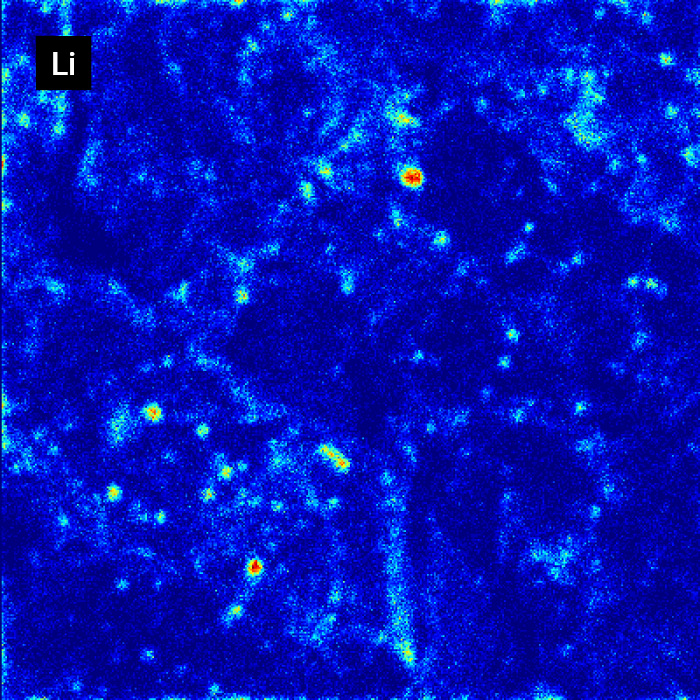

By utilizing 3D FIB-SEM tomography combined with ToF-SIMS analysis, we can conduct detailed investigations of the material composition in new battery technologies. This 3D approach delivers more precise volumetric statistical data than traditional ToF-SIMS depth profiling. Moreover, 3D ToF-SIMS tomography aids in pinpointing contaminants, vulnerabilities, and chemical inconsistencies within the battery components.

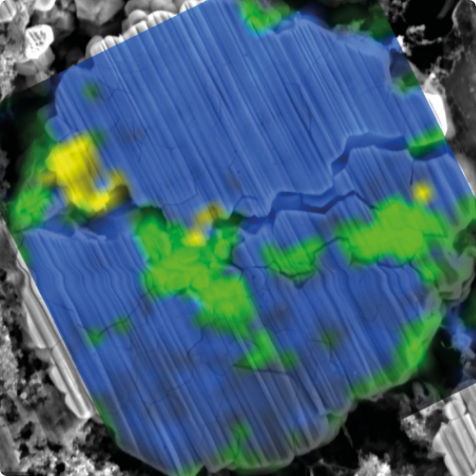

Solid Electrolyte Interface Characterization in Battery Technology

A significant factor influencing the lifespan and (dis)charge rate of the lithium-ion battery within new battery technology is the formation of a solid electrolyte interface (SEI). This nanometer-scale thin passivation layer prevents anode particles from direct contact with the electrolyte, thus preventing corrosion and facilitating swift lithium-ion movement during the (de)intercalation process.

By integrating ToF-SIMS into the FIB-SEM system, we can delve deep into SEI properties, such as its distribution, uniformity, and chemical composition on anode particles surfaces. This technique is especially adept at detecting light elements like Li, C, O, F that are typically present in the SEI, and studying its depth distribution.

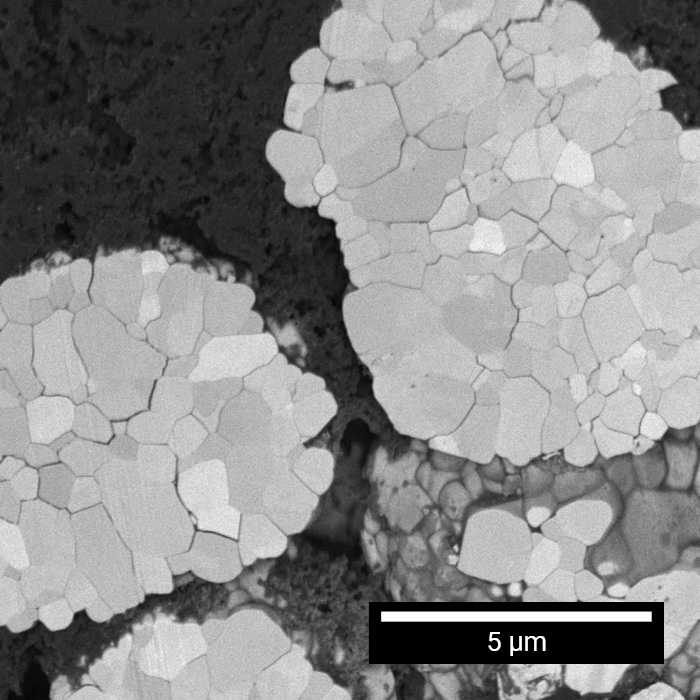

Solid-State Battery Degradation Study

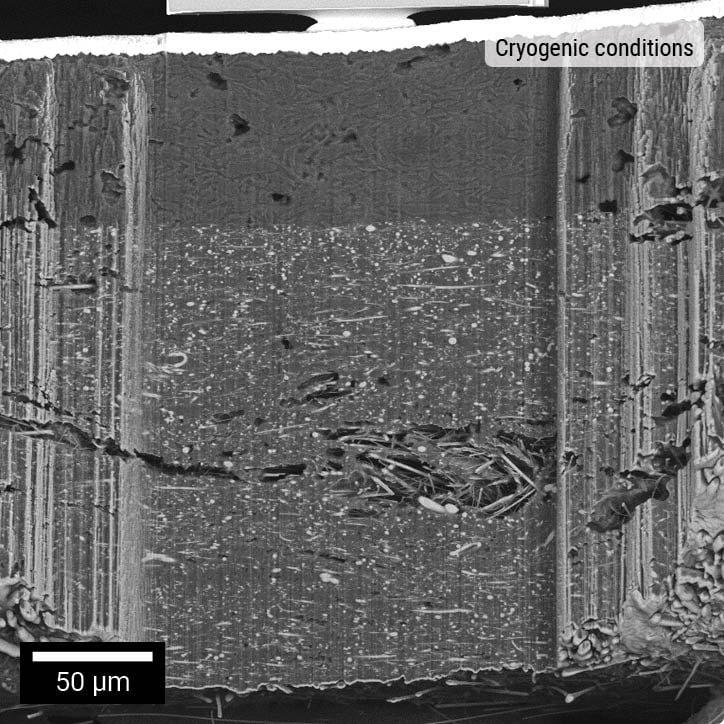

While solid-state batteries offer a potential alternative to the drawbacks of lithium-ion batteries, namely flammability, low thermal stability, and limited performance and strength, they too are susceptible to degradation. Issues like cracking within the solid electrolyte can lead to electrically isolated areas and subsequent battery capacity fade.

The FIB-SEM system is indispensable for preparing cross sections of the entire electrode–electrolyte battery structure. This allows for the identification of cracks and, if the solid-state electrolyte is ion beam-sensitive, the application of cryogenic conditions to minimize damage and reduce material redeposition during the FIB milling processes.

Electrode Particle

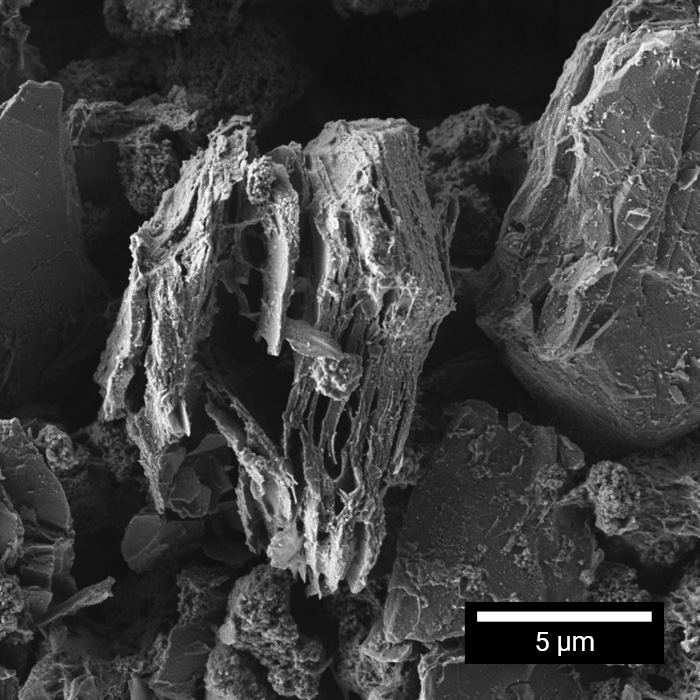

Degradation Study

The lifespan of a lithium-ion battery is often compromised by anode/cathode particle degradation, which is primarily due to exfoliation, fracturing, and corrosion. This degradation, triggered by mechanical stresses during lithium movement as well as chemical reactions, notably diminishes battery capacity.

With the FIB-SEM system, we can identify particle degradation both on and below the battery electrode surface. The focused ion beam within the FIB-SEM system facilitates the preparation of cross sections, enabling comprehensive studies of particle degradation origins using SEM, Raman spectroscopy, ToF-SIMS chemical mapping, even in a volume using 3D ToF-SIMS tomography.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN, and solutions for batteries or other topics.