Join Our Webinar: Unveiling TESCAN’s FIB-SEM Solutions for Semiconductor Failure Analysis

The continuous drive for miniaturization, efficiency, and integration in semiconductor devices is pushing boundaries in both design and manufacturing. As a result, the challenges faced by researchers and engineers in failure analysis (FA) and sample preparation are more complex than ever.

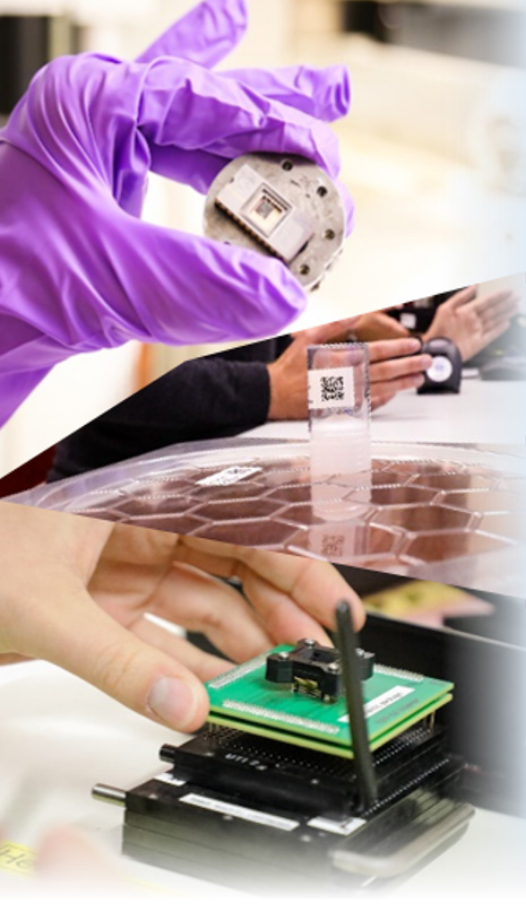

For professionals working in this space, having reliable and efficient tools to prepare and analyze samples is critical to maintaining progress. This is why we invite you to our upcoming webinar to explore our suite of FIB-SEM solutions, designed specifically for semiconductor FA and R&D laboratories.

In this online session, we’ll be walking through the role these systems play in sample preparation workflows, highlighting how precision, automation, and ease of use can boost your lab’s productivity.

Event Details:

-

Title: Introduction to TESCAN’s FIB-SEM Solutions for Semiconductor Failure Analysis and R&D Laboratories

-

Date & Time: Mon, Oct 21, 2024 5:00 PM - 6:00 PM CEST

Why This Webinar is Relevant for You

If you’re working with advanced semiconductor devices, you’re no stranger to the growing complexity of failure analysis. The industry’s shift toward 3D integration, high-density packaging, and increased functionality demands a level of analysis that conventional techniques can’t always provide. TESCAN’s solutions are engineered to meet these demands head-on.

During this session, we’ll explore how our Gallium and Xenon FIB-SEM platforms streamline processes such as sample cross-sectioning, TEM preparation, and delayering. More specifically, we’ll dive into the correlative use of laser and FIB technologies, the role of AI in automating TEM sample preparation, and how to enhance precision during localized delayering with in-situ nanoprobing.

Whether you’re managing large sample volumes or tackling advanced packaging investigations, this webinar will equip you with insights that you can directly apply to your lab’s daily operations.

Key Takeaways for Semiconductor Professionals

The upcoming webinar will offer a deep dive into several critical processes and solutions for FA and R&D labs. Here’s what you can expect:

-

Optimized Workflow for Advanced Packaging Investigations: Learn how combining laser systems with TESCAN’s FIB-SEM platforms, particularly the SOLARIS X 2, can streamline your analysis of complex semiconductor packages.

-

AI-Driven Automation in TEM Sample Preparation: Discover how TESCAN’s systems integrate AI to automate precise, repeatable TEM sample preparation on both Gallium and Xenon FIB systems, enhancing productivity while maintaining high-quality results.

-

Localized Planar Delayering with In-Situ Nanoprobing: Explore how the AMBER X 2 system facilitates delayering and in-situ probing, offering unparalleled accuracy in investigating defects within logic and memory devices.

-

Maximizing Throughput and Precision: Understand how our FIB-SEM solutions are tailored to meet the increasing demands for precision and efficiency in failure analysis, ensuring your lab stays competitive.

Why You Shouldn’t Miss This Opportunity

As semiconductor devices evolve, so must the tools we use to analyze them. If you’re looking for ways to enhance your lab’s capabilities, improve sample throughput, or simply stay informed on the latest approaches in semiconductor failure analysis, this webinar is for you.

Sign up today to secure your spot and take the opportunity to engage with experts who will share best practices, real-world applications, and strategies for tackling the most challenging aspects of semiconductor failure analysis.

Don’t miss this chance to gain actionable insights - Register now and prepare to elevate your lab’s performance with the right tools!

AI/ML-Enhanced Techniques: Improving Efficiency and Accuracy in Failure Analysis

FA 4.0 aims to transform the failure analysis field by developing advanced equipment and methods, utilizing the capabilities of artificial intelligence, machine learning, and automation. The project's main innovations include:

- § Advanced devices and equipment for failure analysis

- § Incorporation of AI/ML-driven algorithms for image and signal analysis to improve tool performance

- § Simplifying complex workflows by interconnecting devices with novel hardware interfaces

- § Centralizing diagnostic data collection and correlation for efficiency

- § Detailed defect mode detection and cataloging, incorporating metrology and electrical test data

An international consortium from Germany, France, and the Czech Republic, including industry leaders such as Infineon, STMicroelectronics, and BOSCH, have collaborated with SMEs, medium-sized companies, and renowned research institutes to realize this project.

Enhancing Failure Analysis with AI/ML-Driven Solutions

FA 4.0 is focused on maximizing the potential of AI/ML solutions to transform failure analysis. By using standardized hardware and software, the project aims to integrate tools and FA databases, enabling streamlined workflows. This approach facilitates the development of advanced AI/ML solutions, improving FA quality and productivity, and enabling failure analysis engineers to work more efficiently.

FA 4.0 is expanding current FA capabilities for measurement evaluation with signal and image-based AI/ML methodologies. These advanced techniques include AI/ML-driven evaluations of raw signals from detectors in SEMs and FIBs, as well as acoustic echoes in Scanning Acoustic Microscopes and X-Ray signals in micro CT. This enables the development of next-generation FA tools, promoting AI/ML-based, integrated workflows that enhance productivity and quality in the future of failure analysis.

Looking Towards the Future of Failure Analysis

By September 2023, TESCAN and project partners aim to implement a fully functional workflow comprising:

- § Package defect localization/identification in PVA TEPLA's Scanning Acoustic Microscope

- § Large volume material removal on the shared FA 4.0 stage using 3D-Micromac's laser micromachining tool,with data transfer via image header

- § Fine sample preparation and defect analysis with SOLARIS X.

In conclusion, TESCAN and its FA 4.0 partners aim to pioneer a new phase of failure analysis, where AI/ML-driven solutions and automation enhance efficiency, accuracy, and reliability. We strive to shape the future of electronic systems and improve Europe's standing in the field of smart mobility and industrial production.

Join us as we continue this significant endeavor to redefine failure analysis!