FA 4.0: Developing Advanced Failure Analysis Equipment and Methods

Incorporating Artificial Intelligence/Machine Learning (AI/ML) and Automation for Improved Defect Recognition and Efficiency

TESCAN is part of an ongoing project, set to conclude in September 2023, called Failure Analysis (FA) 4.0. This project is focused on addressing the reliability and safety challenges within the fast-paced electronic systems industry. As a significant participant, TESCAN has co-developed AI/ML-driven tools and methodologies for detecting and mitigating defects in electronic components and systems. This approach aims to refine the processes of design, manufacturing, and maintenance for high-tech products, enhancing Europe's role in smart mobility and industrial production.

AI/ML-Enhanced Techniques: Improving Efficiency and Accuracy in Failure Analysis

FA 4.0 aims to transform the failure analysis field by developing advanced equipment and methods, utilizing the capabilities of artificial intelligence, machine learning, and automation. The project's main innovations include:

- Advanced devices and equipment for failure analysis

- Incorporation of AI/ML-driven algorithms for image and signal analysis to improve tool performance

- Simplifying complex workflows by interconnecting devices with novel hardware interfaces

- Centralizing diagnostic data collection and correlation for efficiency

- Detailed defect mode detection and cataloging, incorporating metrology and electrical test data

An international consortium from Germany, France, and the Czech Republic, including industry leaders such as Infineon, STMicroelectronics, and BOSCH, have collaborated with SMEs, medium-sized companies, and renowned research institutes to realize this project.

Enhancing Failure Analysis with AI/ML-Driven Solutions

FA 4.0 is focused on maximizing the potential of AI/ML solutions to transform failure analysis. By using standardized hardware and software, the project aims to integrate tools and FA databases, enabling streamlined workflows. This approach facilitates the development of advanced AI/ML solutions, improving FA quality and productivity, and enabling failure analysis engineers to work more efficiently.

FA 4.0 is expanding current FA capabilities for measurement evaluation with signal and image-based AI/ML methodologies. These advanced techniques include AI/ML-driven evaluations of raw signals from detectors in SEMs and FIBs, as well as acoustic echoes in Scanning Acoustic Microscopes and X-Ray signals in micro CT. This enables the development of next-generation FA tools, promoting AI/ML-based, integrated workflows that enhance productivity and quality in the future of failure analysis.

Looking Towards the Future of Failure Analysis

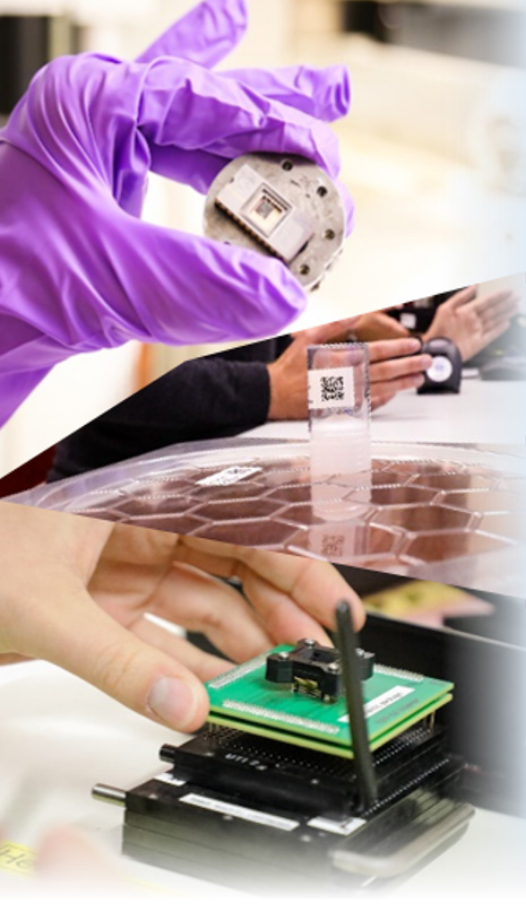

By September 2023, TESCAN and project partners aim to implement a fully functional workflow comprising:

- Package defect localization/identification in PVA TEPLA's Scanning Acoustic Microscope

- Large volume material removal on the shared FA 4.0 stage using 3D-Micromac's laser micromachining tool,with data transfer via image header

- Fine sample preparation and defect analysis with SOLARIS X.

In conclusion, TESCAN and its FA 4.0 partners aim to pioneer a new phase of failure analysis, where AI/ML-driven solutions and automation enhance efficiency, accuracy, and reliability. We strive to shape the future of electronic systems and improve Europe's standing in the field of smart mobility and industrial production.

Join us as we continue this significant endeavor to redefine failure analysis!

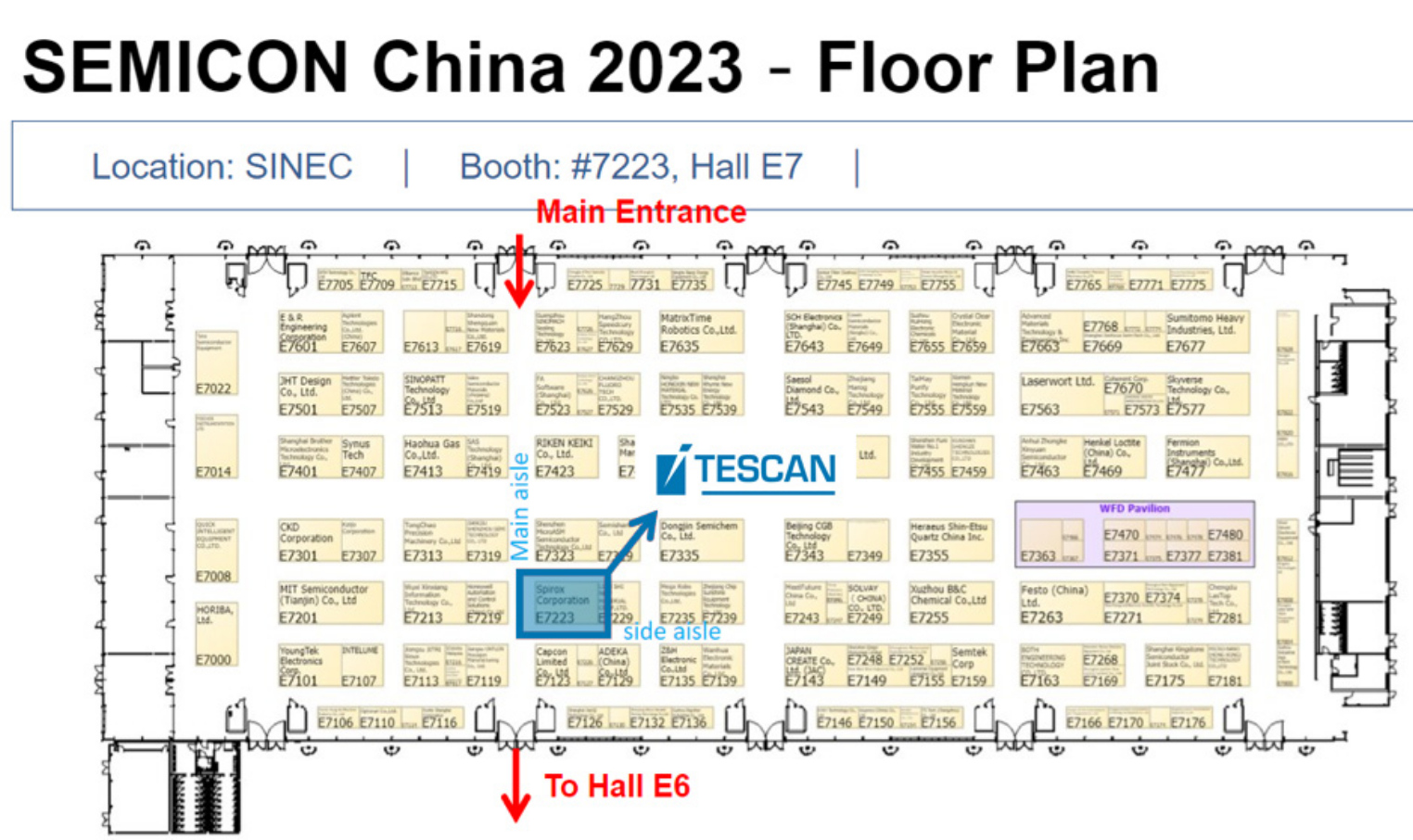

Discover the latest in Semiconductor Technology

Join industry professionals, researchers, and academics in exploring the future of semiconductors. Our team of experts is looking forward to engaging with industry professionals, researchers, and academics, learning about your requirements, and discussing how TESCAN's solutions can support your research and development initiatives.