TESCAN SOLARIS X 2

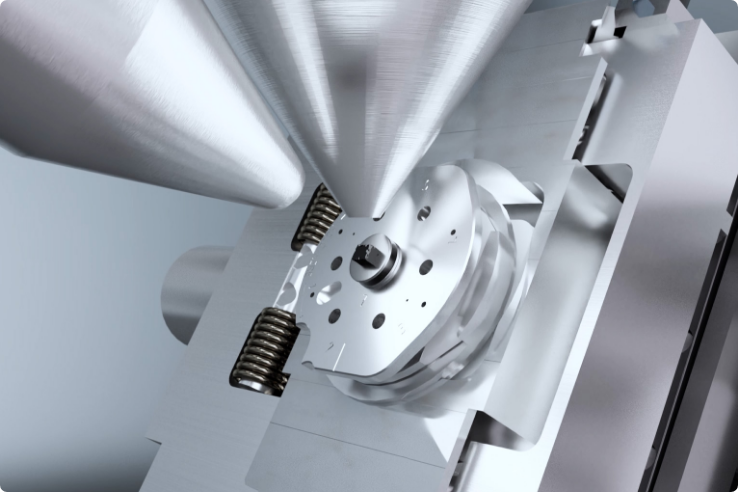

Powered by Mistral™ Plasma FIB column

Boost Your Package-Level Failure Analysis with Advanced Deep Sectioning and High-Resolution End-Pointing

Enhanced Sample Preparation Throughput

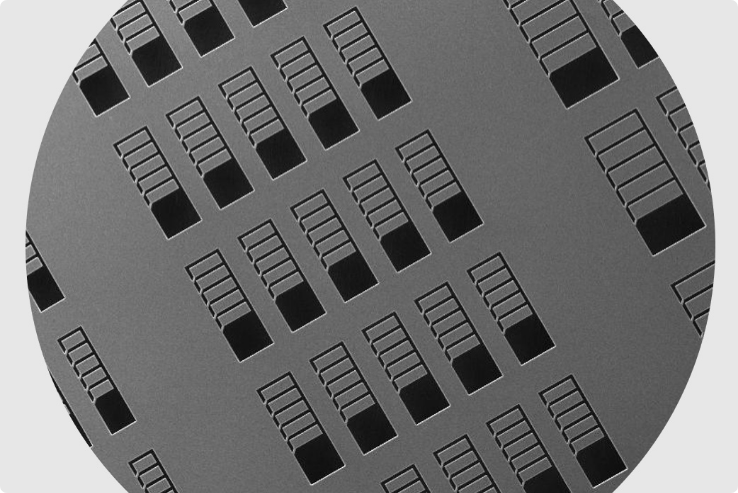

TESCAN SOLARIS X 2 extends FIB physical failure analysis capabilities to large-area applications, making deep cross-sectioning of advanced packaging devices, displays, MEMS, and optoelectronic devices more efficient.

Featuring the new generation Mistral™ Xe Plasma FIB column, SOLARIS X 2 offers increased maximum ion beam current and a sharper ion beam profile across the full range, with significantly reduced beam tails. This allows operators to use higher milling and polishing currents, achieving superior surface quality comparable to conventional Plasma FIB, but with greater speed and precision.

SOLARIS X 2: Expanding Plasma FIB-SEM Capabilities for Large and Small-Scale Applications

As TESCAN’s flagship Plasma FIB-SEM microscope, SOLARIS X 2 is designed to deliver ultimate resolution and signal strength at the FIB and SEM beams coincidence point. This precision enables operators to accurately end-point on the smallest defects within complex IC package stacks, HBM memories, and other heterogeneously integrated devices.

Enhanced ion beam properties reduce typical FIB artifacts, minimizing the need for alternative high current polishing methods, and enabling automated TEM lamella preparation and efficient sub-100 µm cross-sectioning.

How TESCAN SOLARIS X 2 Fits Your Needs

Purpose-Driven Performance

Accelerate physical failure analysis with the fast material removal capabilities of the Xe Plasma FIB beam.

Deep Sample

Access

Reach buried structures up to 1 mm in depth using ion beam currents up to 3.3 μA.

Precision

at the Nanoscale

Achieve precise end-pointing with nanometer accuracy during milling or cross-sectioning, thanks to the high-resolution imaging of the Triglav™ SEM column.

Superior Surface Sensitivity

Conduct ultra-high-resolution imaging on beam-sensitive materials with the Triglav™ SEM column, designed for excellent surface sensitivity and contrast.

Pristine Sample Preservation

Prepare high-quality, damage-free TEM samples using the inert Xe ions of the Plasma FIB beam, avoiding Ga implantation or surface damage.

Artefact-Free

Cross-Sections

Create clean, artifact-free cross sections, even on challenging materials, using our patented Rocking Stage for alternating milling angles and TRUE X-sectioning for optimal ion beam use at high currents.

Register for Our Webinar to Discover More about TESCAN Plasma FIB-SEM

Watch the TESCAN Deep-Sectioning

Webinar

Analyze Complex Failures in Next-Gen IC Packages and Devices

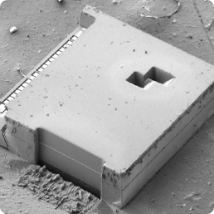

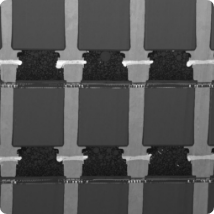

TESCAN SOLARIS X 2 excels in the physical failure analysis of advanced stacked IC packages (2.5D, 3D IC), flip-chips, MEMS devices, OLED and TFT displays, MLCC capacitors, 3D NANDs, and more.

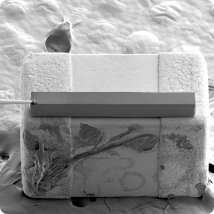

Uncover Sub-Surface Features: Precision Ga-Free TEM Lamellae for STEM Analysis

Produce high-quality, Ga-free TEM lamellae under 100 nm thick from package and IC-level samples, ideal for subsequent STEM analysis.

Unveil Material Secrets with In-Depth 3D EDS & EBSD Microanalysis

Leverage fast, large-volume 3D EDS and EBSD microanalysis for advanced packaging devices such as solder balls, TSVs, and bond pads, enabling comprehensive material composition analysis and characterization.

Key Benefits of TESCAN SOLARIS X 2

Localized Failure Analysis

Perform highly localized sub-mm scale physical failure analysis with the Mistral™ Xe Plasma FIB column, delivering maximum ion beam currents up to 3.3 µA for rapid material removal.

Artifact-Free Cross Sections

Produce clean cross sections free of curtaining and terrace artifacts, even on difficult materials like polyimide, SiC, ceramics, and glass, with our integrated Rocking Stage and TRUE X-sectioning technology to optimize milling angles and suppress ion beam tails.

Maximized Throughput and Readiness:

Ensure consistent results and reduce setup times with fully automated electron column and Xe Plasma FIB column alignments.

User-Centric Productivity:

Increase productivity for all users with TESCAN’s advanced workflows and guided wizards in the Essence™ graphical user interface.

Boost your analyses with these solutions

TESCAN Rocking Stage

Achieve Artifact-Free FIB Cross-Sectioning and Precise SEM End-Pointing for Challenging Samples.

TESCAN True X-Sectioning

Save time with ripple-free plasma FIB cross-sectioning that doesn't compromise the high beam current advantage.

.

Questions?

Want a virtual demo?

Our global team is ready to answer questions about TESCAN FIB-SEMs and our solutions for Semiconductors and IC Packaging Failure Analysis.