Automated Delayering

EssenceTM Module Efficiency

Seamlessly integrate the TESCAN EssenceTM Module for automated, precise semiconductor delayering.

Key Benefits of TESCAN Automated Delayering

Efficient Resource Utilization

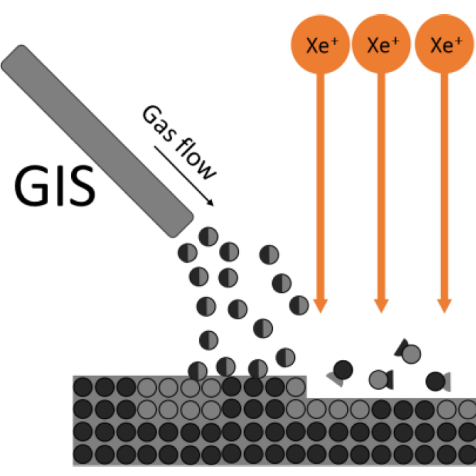

Empower your research with a system that utilizes pre-programmed recipes for unattended, consistent Plasma FIB delayering, preserving device integrity.

Proprietary Chemistry Integration

Benefit from the synergy of Xe Plasma FIB with TESCAN's gas chemistry crafted for optimal delayering across contemporary semiconductor nodes.

.png?width=734&height=617&name=image1_higher%20kopie%20(1).png)

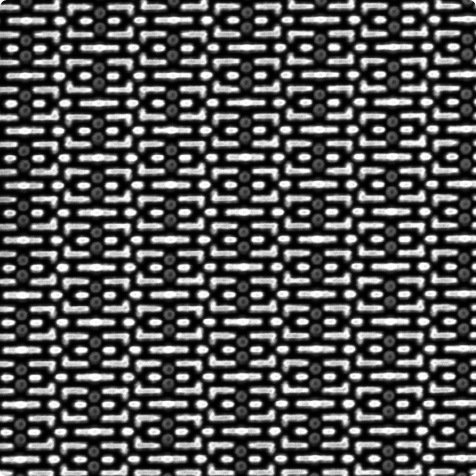

Automated delayering through several bottom layers of 7 nm FinFET CPU device using Nanoflat and C-maze chemistry.

Customization and

Consistency

Craft and apply unique delayering processes with predefined templates, ensuring uniform application and repeatability across samples.

In-depth

Monitoring

Track delayering progress with sophisticated end-point detection, leveraging peak recognition within the TESCAN Delayering module for precision halting.

Uninterrupted

Assurance

Rely on automated processes designed to terminate delayering before reaching critical layers, safeguarding device functionality.

Advanced Applications for EssenceTM Automated Delayering

Enhanced Imaging

Utilize sub-1 kV SEM imaging for distinct voltage contrast and swift failure identification.

Chemistry Options

Choose from diverse delayering chemistries like Nanoflat, Chase, and C-maze, tailored for various sample types.

EssenceTM Module

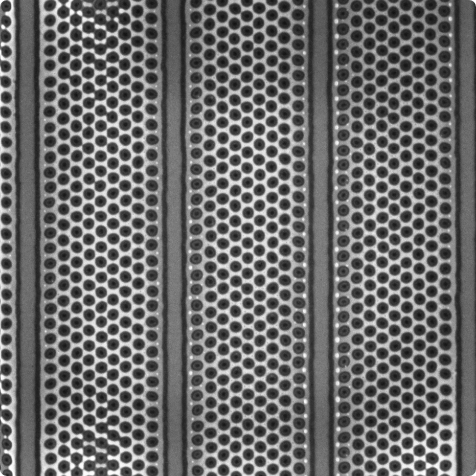

Leverage the Essence Delayering module for uniform etching across the 3D NAND stack, ensuring thorough analysis.

Questions?

Want a virtual demo?

Our global team is ready to answer questions about TESCAN FIB-SEMs and our solutions for Semiconductors and IC Packaging Failure Analysis.