TESCAN AMBER X 2

Advanced Semiconductor

Delayering

TESCAN AMBER X 2 for Delayering

Uniform

Delayering

Achieve consistent, artifact-free delayering by leveraging our tailored Nanoflat Chase and C-maze gas chemistries optimized for sub-10 nm technology nodes.

Device

Integrity

Preserve electrical properties with our precise, low kV Plasma FIB milling, employing inert Xe ions for delicate sample processing.

Failure

Localization

Streamline defect isolation with our refined in-lens detection, engineered for effective passive voltage contrast imaging.

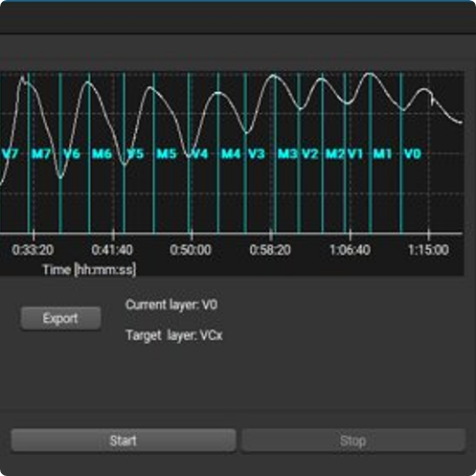

Delayering

Automation

Simplify end-point determination with our intelligent TESCAN DelayeringTM software, automating delayering to the targeted layer.

Electrical

Analysis

Facilitate in-situ verification or characterization of electrical failures using compatible industry-leading nanoprobing solutions.

User

Productivity

Boost operational efficiency for users at all expertise levels with the intuitive TESCAN EssenceTM graphical user interface.

Discover TESCAN AMBER X 2

for Delayering

The Advantages of TESCAN AMBER X 2 for Delayering

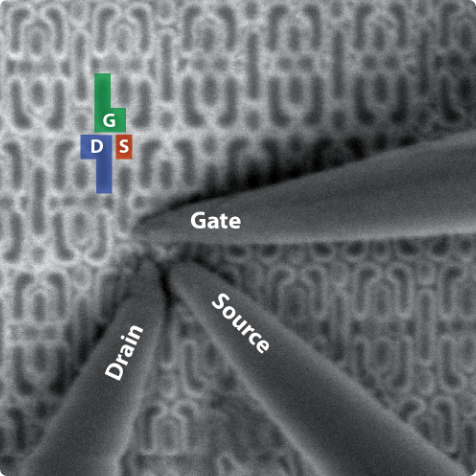

Utilize SEM-Based Nanoprobing for detailed characterization of NMOS and PMOS transistors across various semiconductor nodes, facilitating precise layer targeting for effective delayering.

In-depth SEM-based Nanoprobing

Leverage sophisticated SEM-based

Nanoprobing to accurately

characterize NMOS and PMOS

transistors across a spectrum of

semiconductor nodes, including

22, 14, 10, and 5 nm.

Targeted Uniform Delayering

Attain meticulous uniform delayering, empowered by advanced automation that intelligently identifies and halts at your designated layers within the stack.

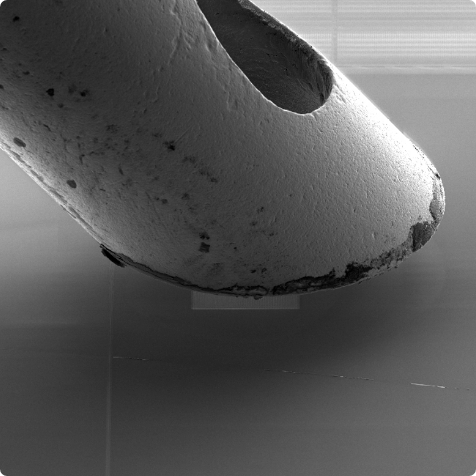

Consistent Large-Area Delayering

Ensure expansive, uniform delayering over large areas measuring 300 × 300 μm2, utilizing our specialized "drilled" nozzle.

Questions?

Want a virtual demo?

Our global team is ready to answer questions about TESCAN FIB-SEMs and our solutions for Semiconductors and IC Packaging Failure Analysis.