TESCAN UniTOM XL

A multi-resolution micro-CT optimized for high throughput, diverse sample types, and flexibility for your research.

Download Product Information

High Throughput

An optimized combination of a high-power source, efficient detector and software protocols combine in harmony to provide you with a system tuned to maximize throughput and contrast, reaching temporal resolutions below 10 seconds.

Imaging Flexibility

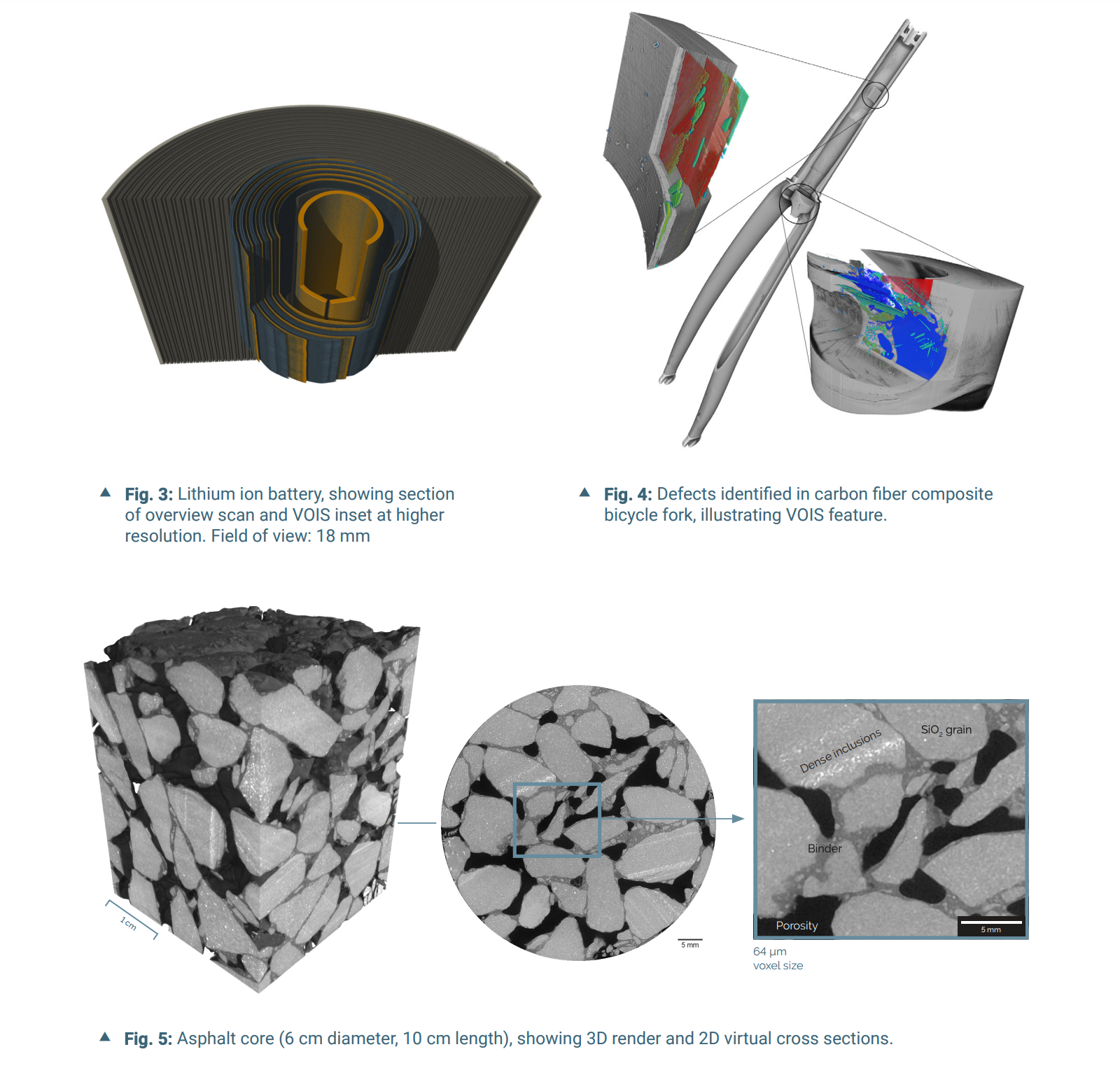

The spacious enclosure facilitates numerous acquisition modes, including Volume of Interest Scanning (VOIS), batch scanning, horizontal and vertical stitching and more. Exert maximum control with access to 9 motorized axes and degrees of freedom.

Wide Array of Samples Types

Flexibility to accommodate your diverse sample types for failure analysis and research applications.

TESCAN UniTOM XL enables high-throughput non-destructive 3D imaging for materials research, failure analysis and quality assurance, including:

Energy Conversion and Storage

Consumer Products and Packaging

Aerospace

Automotive

Medical Devices

Pharmaceutical

Building Materials

Food Science

Advanced Packaging in Electronics

Metals

Modular Design

Components may be added or swapped in the future, with minimal system intervention, providing a ‘future-proof' platform to adapt to tomorrow’s innovations in source or detector technology.

Dynamic Screening for synchrotron Beamtime

TESCAN UniTOM XL can be used as an indispensable test-bed for tuning the complexities of in situ experiments, maximizing your effectiveness and output at the synchrotron.

In Situ Integration and Dynamic CT

In situ devices and related peripheral equipment may be attached to control time-lapse experiments.

Provides an industry-leading level of device connection possibilities, interfaces and software protocols to maximize in situ research.

Continuous scanning via slip ring connection facilitates dynamic CT on a ‘classical’ architecture.

Micro-CT and Additive Manufacturing from 3D to 4D

Watch and learn about the use of Micro CT to understand additive manufacturing. The video introduces micro-CT and 3D approaches, introduces dynamic CT, and shows many dynamic micro CT examples.

Download UniTOM XL Brochure

Learn more about the UniTOM XL

- High Throughput

- Imaging Flexibility

- InSitu Integration

DOWNLOAD FOR FREE TODAY

Composite Wind Blade Engineering

Multi-resolution 3D X-ray CT investigation of porosity from macro to micro-scale

During operation, wind turbine blades are exposed to a wide range of atmospheric and environmental conditions, such as rain or hail. This leads to varying degrees of leading-edge erosion (LEE), depending on the site, operational conditions and blade type.

Download App Note

A Portfolio of TESCAN Dynamic micro-CT Solutions

Is micro-scale non-destructive, 3D imaging compromised without meaningful temporal resolution capabilities? At TESCAN, we passionately believe it is. Consequently, all TESCAN micro-CT solutions are optimized for the highest possible temporal resolution capabilities. This, combined with either optimized spatial resolution, multiscale, or complex in-situ attributes, means that TESCAN brings dynamic CT capabilities to your lab without you having to compromise on any of the other, more traditional micro-CT attributes.

Meet Prof. Martine Wevers and Dr. Jeroen Soete of KU Leuven. They share how Dynamic micro-CT is indispensable for materials engineering and more.

Ready to discuss the TESCAN UniTOM XL?

Please get in touch today.

Our global team will be available to answer questions about the TESCAN UniTOM XL and other solutions from TESCAN.