Download for free today

COMPOSITE WIND

BLADE ENGINEERING

Multi-resolution 3D X-ray CT investigation of porosity from macro to micro scale

During operation, wind turbine blades are exposed to a wide range of atmospheric and environmental conditions, such as rain or hail. This leads to varying degrees of leading edge erosion (LEE), depending on the site, operational conditions and blade type.

Download your copy.

LEE is a well-known phenomenon which has been widely investigated by the aircraft and helicopter industries, although the wind industry appears to have struggled with this issue for a number of years.

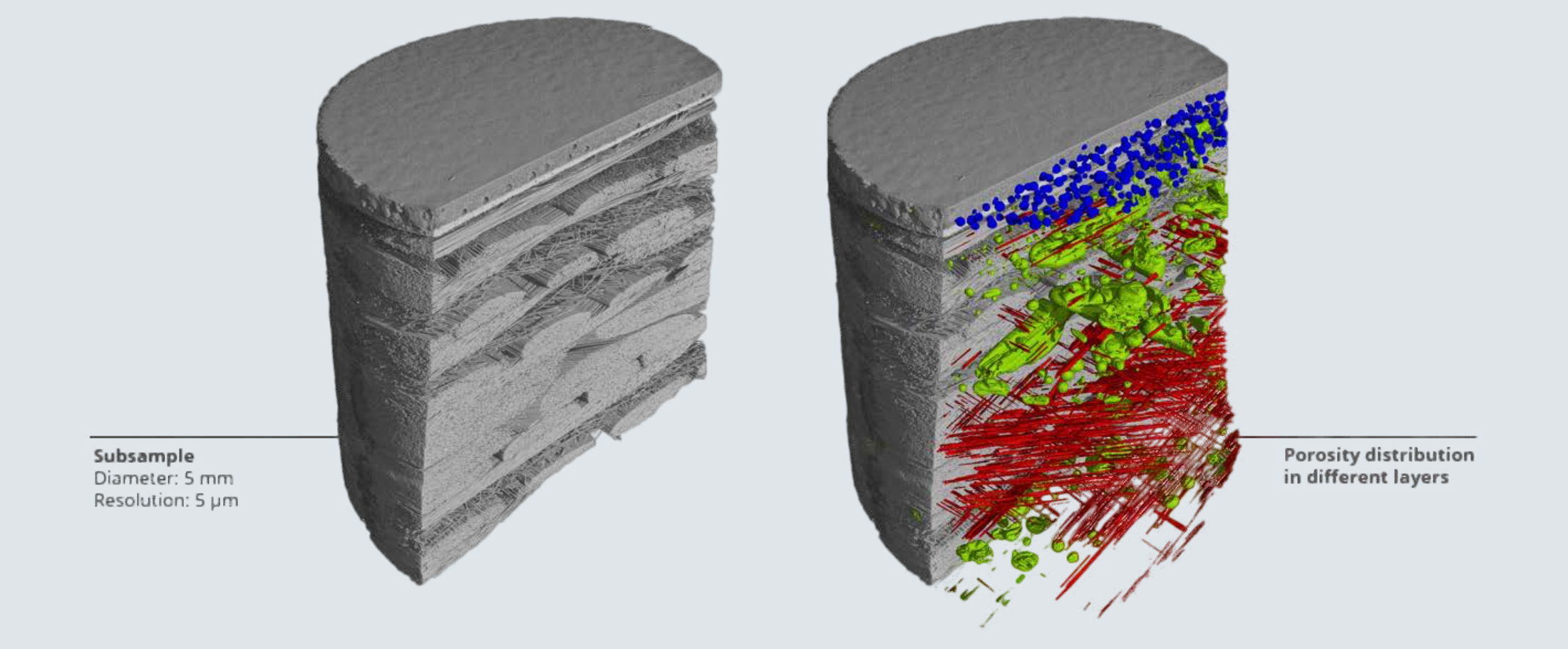

High resolution detailed scan

Subsamples of 5 mm diameter were drilled from representative regions in the larger blade perpendicular on the layers. Subsamples were scanned at 5 μm resolution and provide details on the different layers.

Cross sections through the subsample show the presence of different types of porosity and even individual glass fibers can be discriminated.

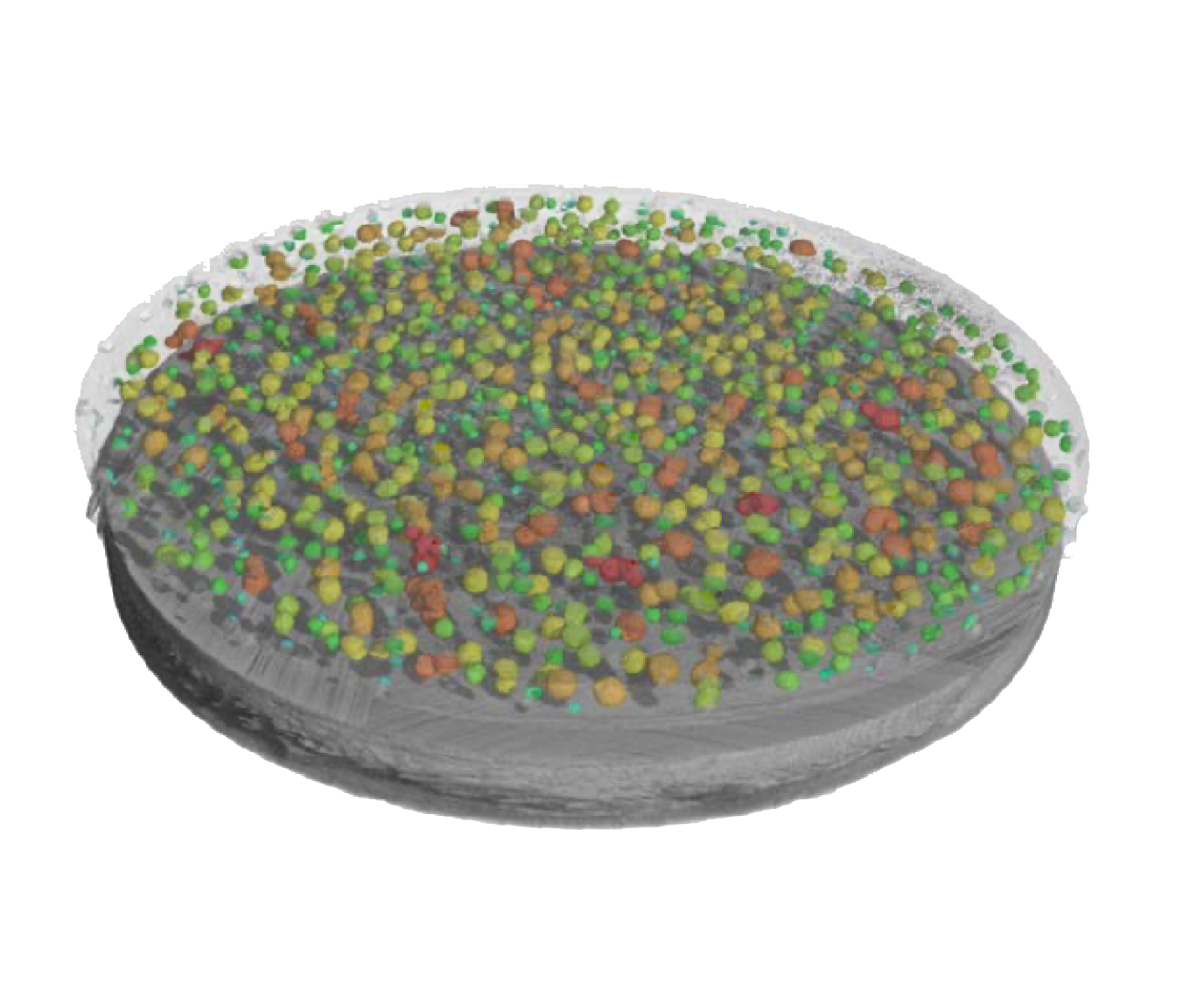

Coating

On top of the composite structure a coating is applied to enhance the material properties. Characterization of those thin and widespread layers is often challenging with traditional methods. In the zoomed in scan the coating was virtually extracted from the rest of the material and an inside look on the coating shows the presence of numerous small air bubbles spread throughout the coating.

Research question

How do structural defects (voids and cracks) affect structural integrity in composite materials for wind energy applications?

Multi-resolution imaging

A composite material is a material that is composed of multiple non-homogeneous materials. It is a complex material both on the macro and micro-scale, requiring a multi-scale imaging approach to obtain a complete overview of the internal structure.

Analysis workflow

All 3D images were obtained on the UniTOM XL, XRE’s flexible and modular multi-resolution X-ray CT system. Complete composite samples (approx. 40 cm in length) were completely imaged to evaluate the internal structure on macroscopic scale. Using the overview image, interesting regions were selected for higher resolution zoom scan. Subsamples were drilled from representative regions to which can be tuned for specific applications to maximize image quality, resolution and throughput. The UniTOM can reach true spatial resolution down to 500 nm and can handle a wide range of sample types and sizes up to 40 cm in diameter and 50 cm in height.

Porosity distribution

Analysis of the pore space in the overview scan of the wind blade part shows that the pattern of the different pores is similar to that of the woven glass fiber structure. Most of the pores detectable in the macrostructure scan can therefore be related to air bubbles trapped between the different glass fiber layers.

The pores in the image above are color-coded according to the equivalent diameter of the pore, where blue represents the smaller pores and red the largest. Most pores have an equivalent diameter below 1 mm. The pore size distribution histogram indicates the need for a more detailed subscan.

Zoom in to get more detail

Simply by selecting a region on the reconstructed overview scan, the UniTOM system can zoom in to the selected region and perform a volume of interest scan (VOIS). In this case a region in the upper left of the blade was selected, as it appears to have some larger pores (red in porosity distribution). The resolution in the detailed VOIS increased over 5 times (12 μm), providing new insights in the structure of the different layers and the presence of larger pores in this zone of the blade.

The presence of larger pores is mainly related to undulations in the inner glass fiber layers and pockets of air between those layers. In the detailed VOIS, pores within the glass fibers layers and within the coating become visible. A crack going through the coating and propagating within the resin below the coating can be discriminated.