TEM lamella preparation with UHR FIB-SEM

Take TEM Sample Preparation to the Next Level

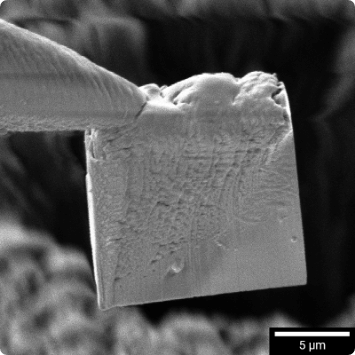

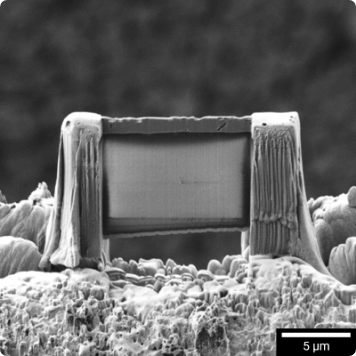

Achieve ultra-thin, flawless, and effortlessly manageable TEM specimens

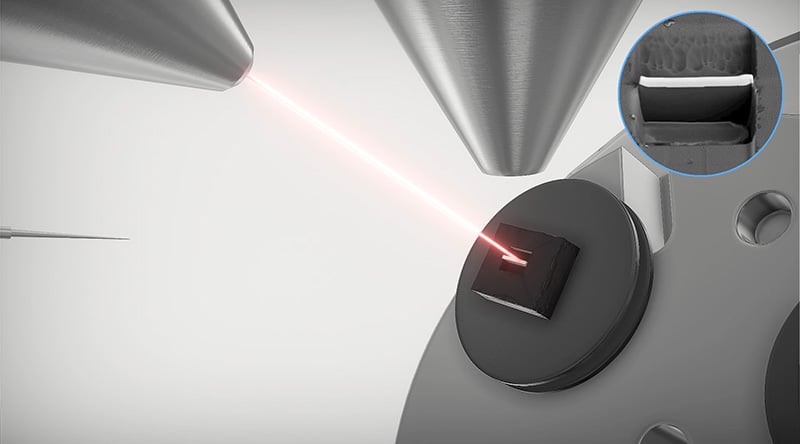

Automate and Accelerate TEM Lamella Preparation

Fast-forward to the future of TEM sample preparation with our TEM AutoPrep™ solutions. Experience a streamlined process that dramatically boosts lab productivity, enhances accessibility, and saves valuable time.

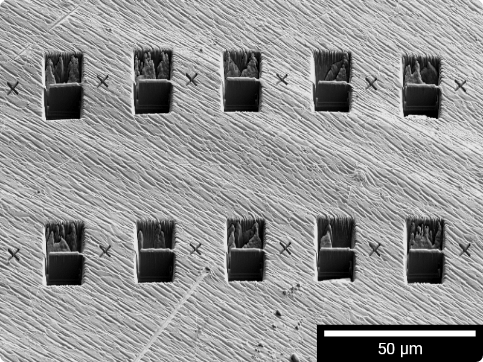

Ever wished to run unattended operations and prepare multiple TEM specimens simultaneously, even overnight? Our intuitive TEM AutoPrep Pro™ solution makes this a reality, simplifying the process for users at all skill levels, from beginners to seasoned experts.

Accelerate your TEM lamella preparation workflow and embrace the speed and ease of TEM sample preparation.

A consistent flow of ultra-thin TEM specimens for everyone

Gone are the days of inconsistent, time-consuming and varying TEM sample preparation. With TESCAN TEM AutoPrep Pro™, the entire workflow is automated, allowing for unattended operations that maximize TEM sample preparation throughput and ensure sample uniformity.

Rest easy knowing that your samples will consistently meet the highest quality standards for subsequent (S)TEM imaging and analysis.

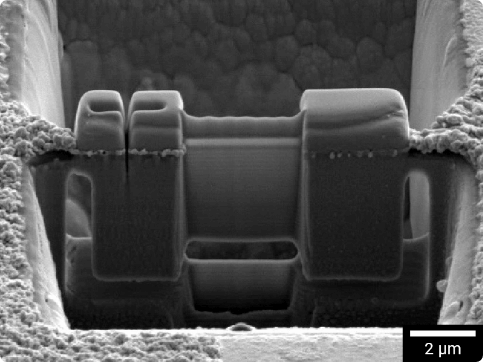

TEM prep automation with effortless precision

From the deposition of a protective layer and sample preparation to sample lift-out, attachment to the TEM grid, and final polishing, TEM AutoPrep Pro™ handles it all. The workflow also includes the low keV polishing step, guaranteeing ultra-high-quality TEM specimens every time.

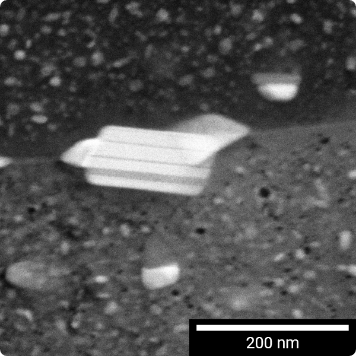

Use cryo and inert transfer for the delicate preparation of liquid, soft and air sensitive materials

Beam, moisture and atmosphere-sensitive, soft liquid or semi-liquid samples can be prepared by characterizing them under cryogenic conditions. Adding a cryo stage enables very low keV Ultra High-Resolution imaging for such samples as well as allowing FIB cross-sectioning and TEM lamella preparation.

TESCAN Cryo TEM preparation

TESCAN systems are proven solutions for TEM lamella preparation in cryo conditions. Lamellae can be prepared on-grid or lifted following cryo workflows.

Embrace automation. Focus on your research.

Let automation handle routine tasks and operate the microscope seamlessly and effortlessly. The automated SEM beam alignment controls most microscope routines, while stable FIB presets and 30 FIB piezo-driven apertures ensure that your FIB is running at optimal performance.

TEM Specimens from the Demanding Materials

Discover unparalleled versatility in TEM specimen preparation tailored for diverse materials, including those sensitive to air or beam exposure. Overcome challenges with unhomogenized samples and advanced geometries, minimizing damage with low keV polishing techniques. Seamlessly integrated into TESCAN TEM AutoPrep ProTM software, our automated TEM lamella preparation technology simplifies high-quality specimen production, accelerating research and adaptation to material properties and milling challenges.

Challenging multiphase and porous

materials? Rotate them!

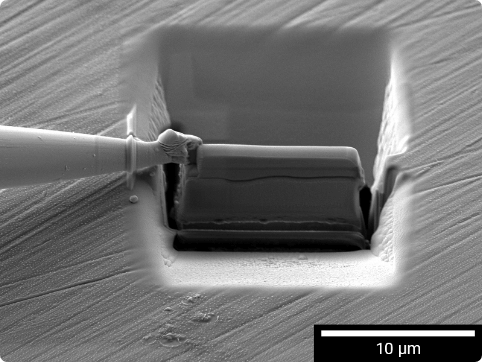

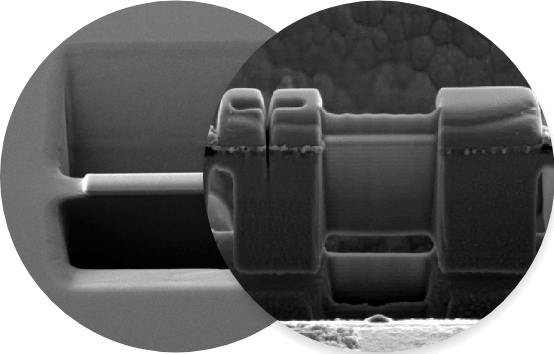

For novel materials, sample thickness is not the only parameter that must be considered. In such cases, advanced lift-out techniques that allow for precise control of the sample orientation, such as rotation, are necessary to prepare a high-quality lamella from the desired geometry.

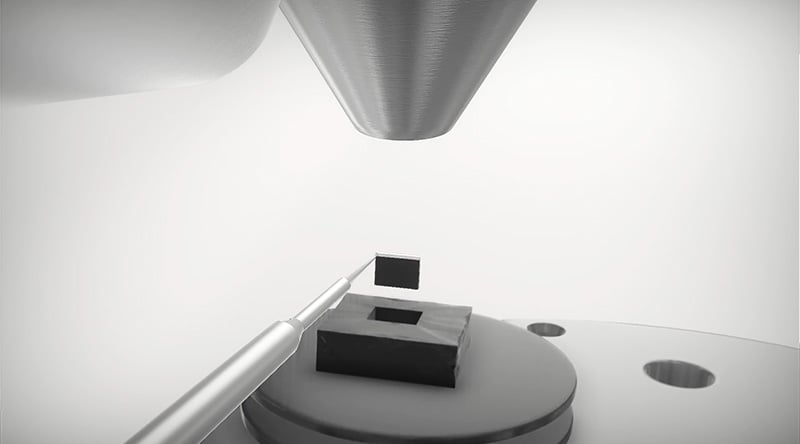

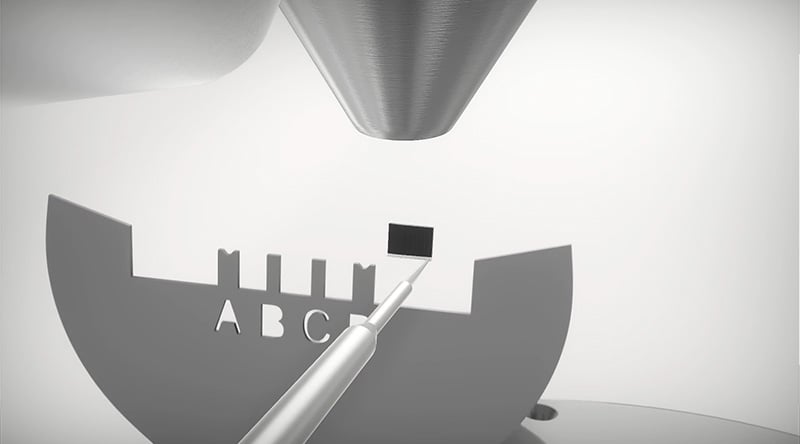

Innovative FIB-SEM Lift-out Solution

For more advanced workflows, a rotatable nanomanipulator is placed in a unique, patented position below the FIB to allow preparation of planar, inverted, and other types of TEM samples without breaking vacuum.

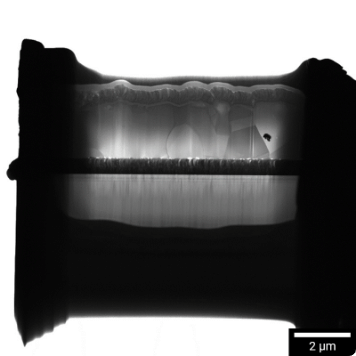

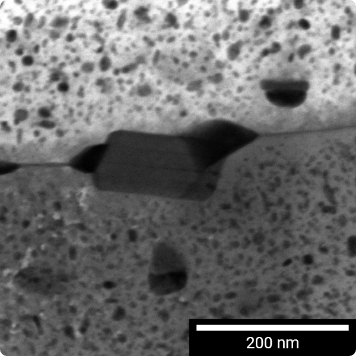

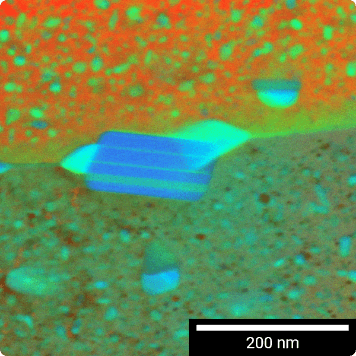

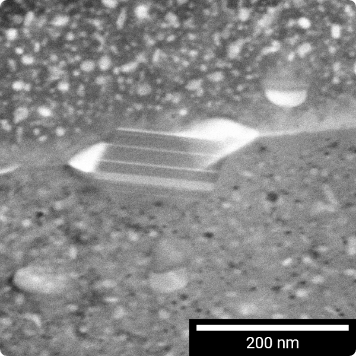

All around STEM sample characterization on your fingertips: STEM, EDS, TKD in SEM

Final TEM sample quality can be easily confirmed directly in FIB-SEM during TEM sample preparation. Retractable STEM detectors characterize samples by taking information from different angles and deliver bright field, dark field, and high-angle dark field contrast. The characterization capabilities can be used not only for quality control of prepared TEM samples, but also for high detail analysis of the prepared samples using techniques like EDX or TKD.

Continuous TEM specimen flow with worry-free sample movements

The sample navigation process may involve movement of both the sample stage and retractable detectors as well as tilting the sample to the required orientation for analysis. Essence™ Collision model is always on guard preventing any hardware collision inside the closed FIB-SEM chamber.

TESCAN Essence™ 3D Collision Model

The Essence™ 3D Collision Model replicates the chamber interior and stage and detector motion, creating a virtual model that prevents collisions and helps users to adjust hardware positions for collision-free movements.

Questions?

Need more information?

Our global team is available to answer questions about TESCAN FIB-SEMs and other solutions from TESCAN.