Enhancing

Mineral

Processing

Efficiency

with Automated

Mineralogy

Enhancing Efficiency and Minimizing Risk in Mineral Separation with Advanced Ore Characterization

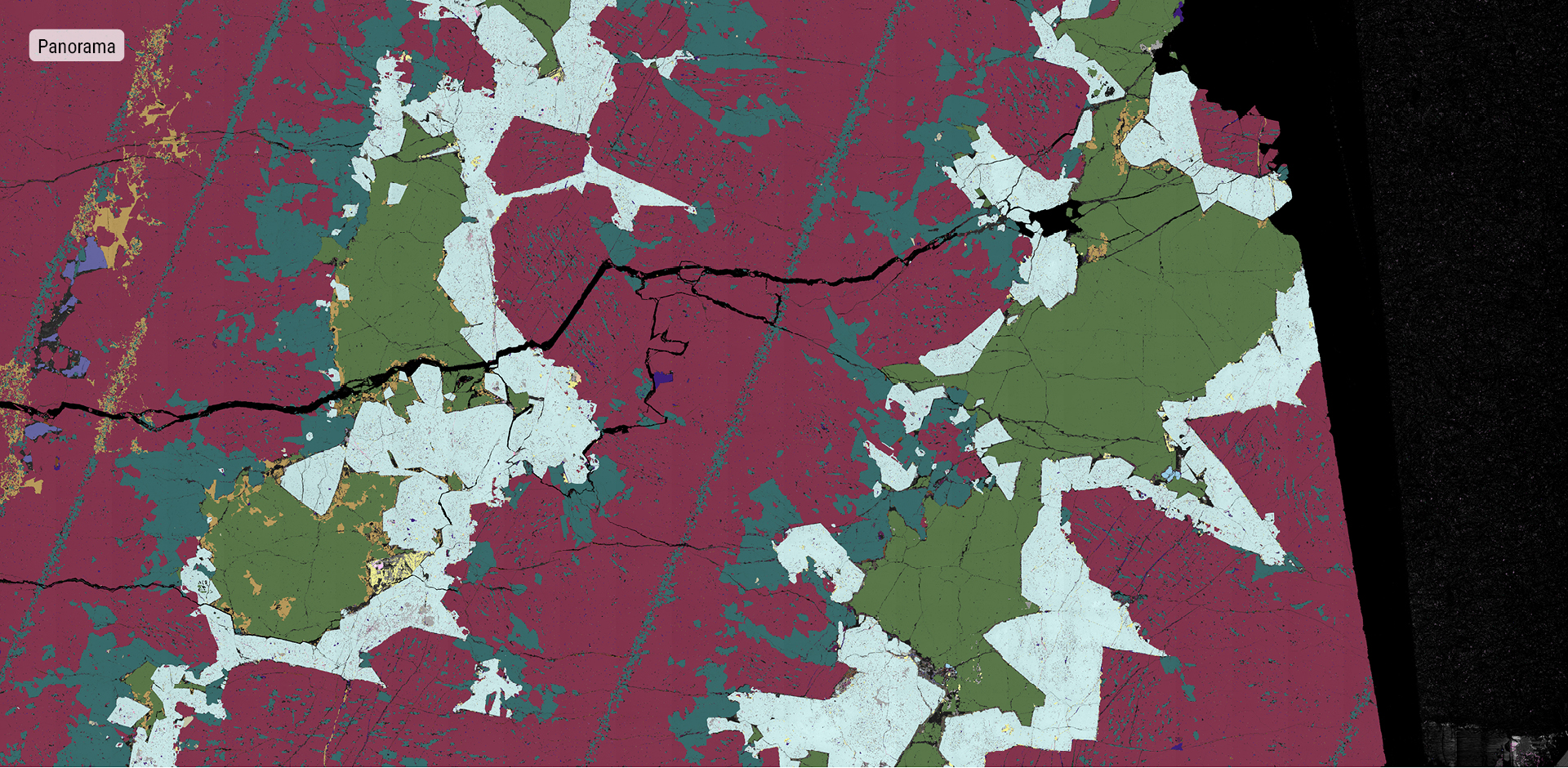

SEM-based Automated Mineralogy emerges as the quintessential technique for in-depth characterization of ore's texture, mineralogy, and chemistry across all stages of the beneficiation process.

TESCAN TIMA excels in this domain, providing micron-scale automated characterization such as:

- Modal Mineralogy: Essential for uncovering sub-one percent mineral grades in feed and identifying processing-impacting minerals, thereby providing clues for optimizing ore processing.

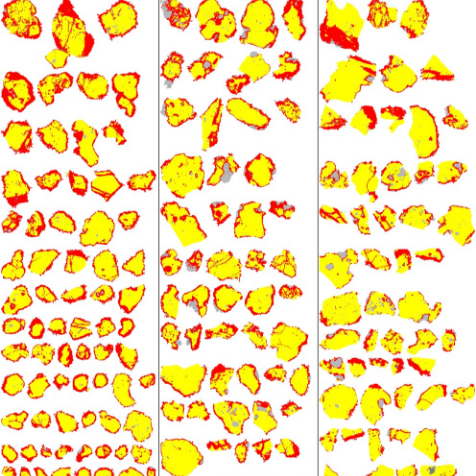

- Mineral Liberation: A critical factor in enhancing beneficiation efficiency, as liberation correlates with higher mineral recovery rates.

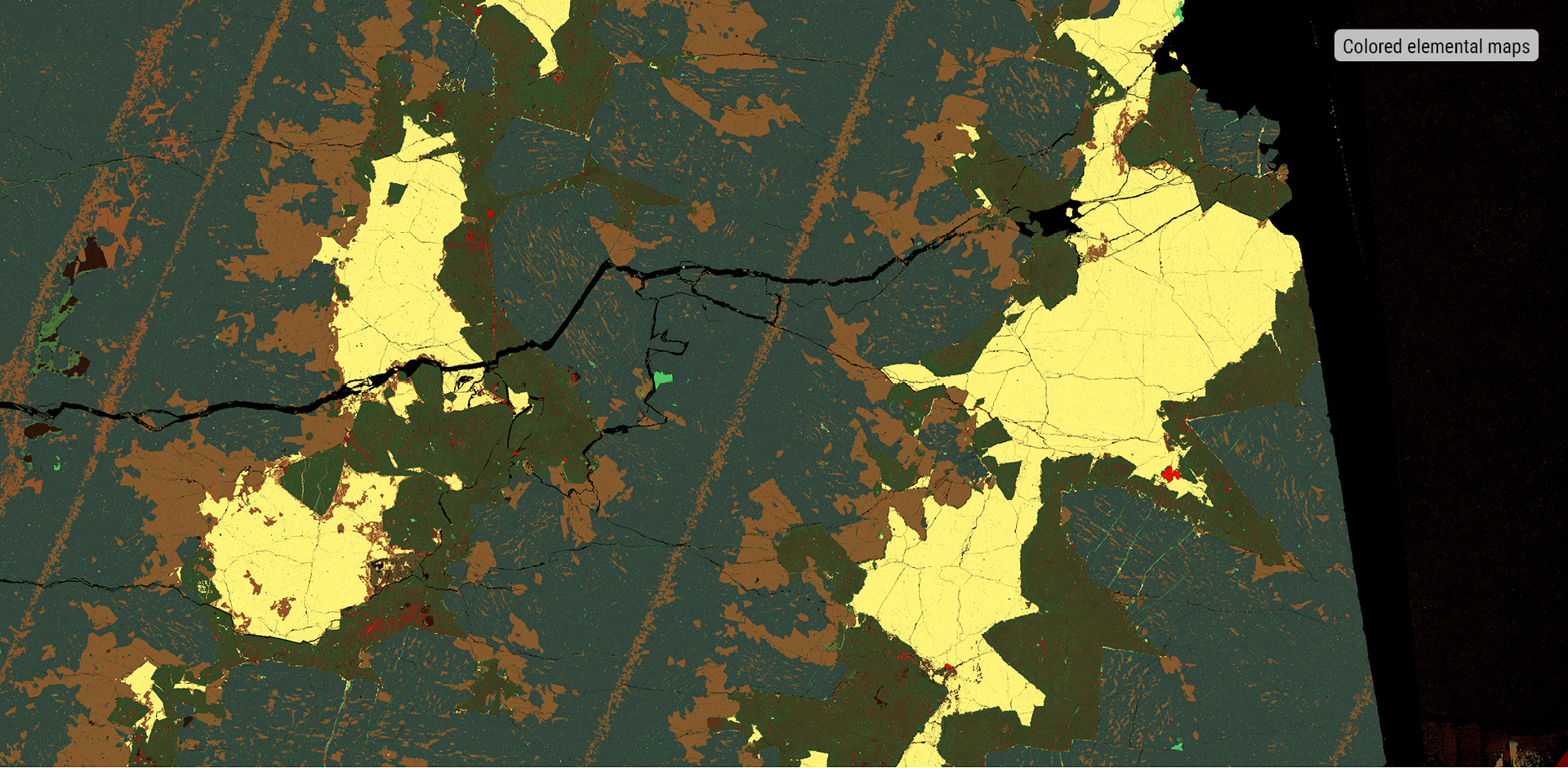

- Elemental Deportment: Offers insights into element distribution among minerals, addressing losses by identifying target elements in unexpected minerals, crucial for process mineralogy.

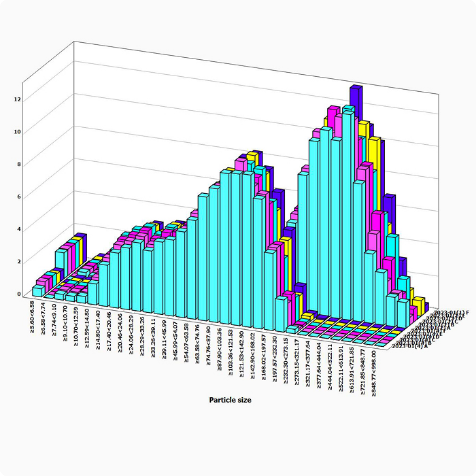

- Size Analysis: Grain Facilitates optimal grind size determination, aiding plant optimization to reduce energy consumption in comminution.

- Mineral Association: Critical for decision-making in mineral separation, like concentrating sulfides with fine gold inclusions rather than gold itself, enhancing flotation and other separation processes.

- Mineral Chemistry: Assesses chemical composition variations affecting the quality of the concentrate, crucial for managing grades and avoiding penalty elements.

Unlocking lithium Ore Value through Advanced Automated Mineralogy Characterization

Efficiently harnessing lithium ore's value necessitates a deep understanding of its lithium content and processing compatibility. TESCAN TIMA is pivotal in optimizing lithium ore processing, from identifying lithium distribution to advising on the best flotation, electromagnetic, or gravity separation techniques.

The system employs texture analysis to evaluate the degree of liberation and the size of grains, thereby optimizing the grinding process. This analysis not only pinpoints loss origins but also reveals valuable byproducts, such as minerals containing tin or tantalum.

Optimizing the Recovery of Metals through Liberation Analysis

TESCAN TIMA stands at the forefront of improving metal recovery through detailed liberation analysis, assessing mineral phase exposure and its impact on recovery efficiency. This analysis, including surface and volume liberation, informs strategies for mineral separation, significantly boosting ore processing outcomes.

Quantifying Fragments of Different Battery Components in Black Mass

Black Mass analysis, crucial for recycling battery materials, demands accurate quantification of fragments of different battery components such as NMC (Nickel Manganese Cobalt), and LFP (Lithium Iron Phosphate) from cathode, graphite from anode or metal foils from charge collectors. Accurately identifying these material proportions is vital for determining the most suitable processing technique and establishing the black mass's value.

TESCAN TIMA stands out in phase-based classification of battery fragments, enhancing the assessment of black mass for processing. This underscores the vital role of automated mineralogy in both recycling and mineral processing strategies.

Questions?

Want a virtual demo?

Our global team is available to answer questions about TESCAN TIMA and its applications in mineral processing and geoscience.