REGISTRATION FORM

Gain the maximum throughput with artifact-free surfaces for sample characterization by using high current plasma FIB-SEM

Presenter: Martin Sláma, Product Marketing Manager - Materials Science

The standard procedure for preparing cross sections using the FIB-SEM technique is to use high currents to remove material quickly, then reduce the FIB current to obtain better beam profile and consequently, a better quality for the final surface. Reducing the maximum current used for final polishing of the section surface, however, results in a longer preparation process. For small cross sections with sizes in the tens of µm, this current reduction method is acceptable. However, as the size of the cross-sectional area to be polished increases, the analysis time increases substantially; therefore, this method is not suitable for preparing cross sections with sizes in the hundreds of µm. To overcome this limitation for large cross sections, plasma FIB was introduced to deliver higher beam currents than those achievable with conventional Ga FIB-SEMs.

Plasma FIB-SEM provides several advantages for sample characterization. First, its high current ion beam is capable of high material sputtering rates which enables efficient preparation of large trenches or cross sections. Plasma FIB also can be used for polishing large surface areas, thereby enhancing sample features and providing more detailed contextual information about structure and composition. about the sample. This can help to reveal material distribution, obtain better statistical information, and link the microscale to the nanoscale sample characterization.

Several technologies have been introduced that improve the implementation of high current plasma FIB for large scale materials characterization. In this webinar, we will walk through the typical plasma FIB cross-sectioning workflow and discuss high current polishing methods. We will present TESCAN’s TRUE X-Sectioning TESCAN Rocking Stage, which was developed to suppress artifacts and improve the final cross-section surface quality when using high beam currents for final polishing. Finally, we will show how plasma FIB-SEM speeds cross-section preparation and enables a greater understanding of your materials by improving 3D FIB-SEM tomography analyses.

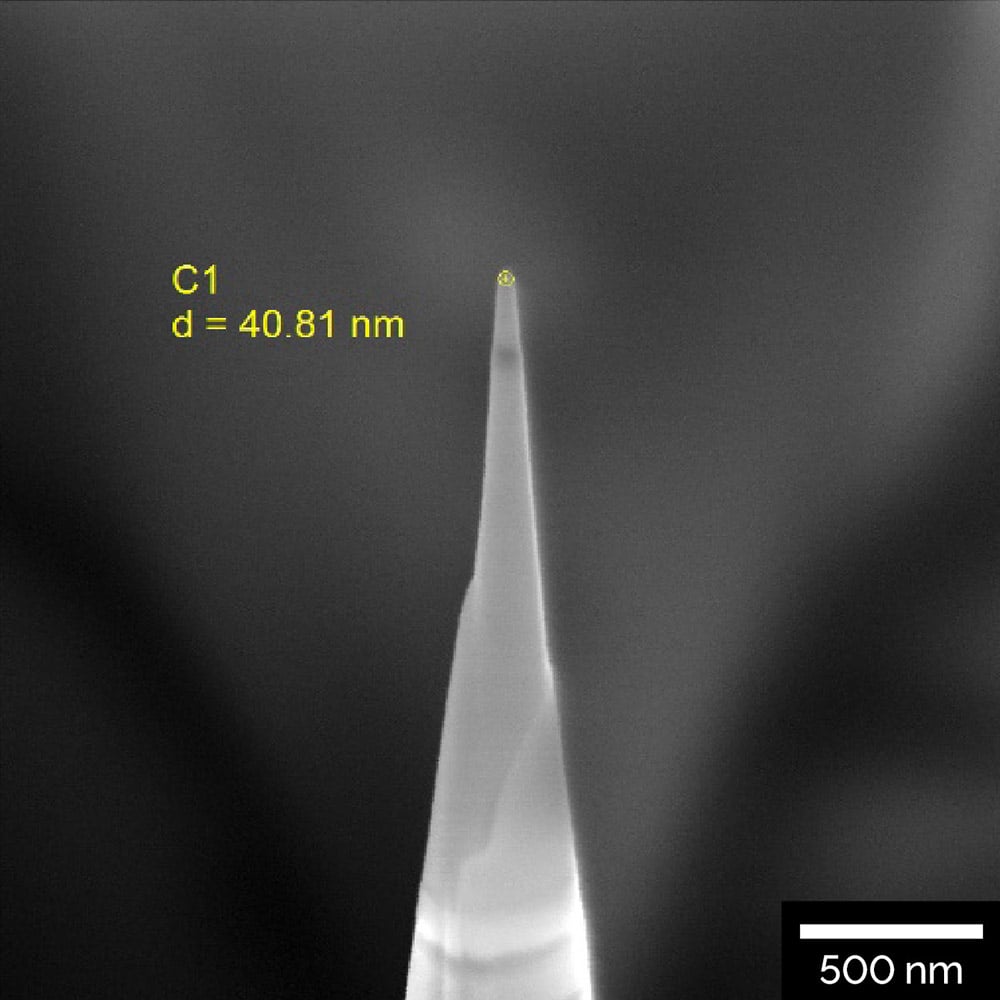

Ga-free atom probe tip-sample preparation using plasma FIB

.png?width=627&name=MicrosoftTeams-image%20(127).png)

1 mm cross-section through a Li-ion battery electrode. High current FIB provides fast material removal and speeds sample polishing

LUNCH WORKSHOP

Materials Science